Our principals

Maco provides a complete range of fire protection solutions for all kinds of off-road vehicles, from the product-line of ANSUL, USA. With their services spread across India, the company provides everything from fire automation detection and suppression systems, to a complete line of wheeled and hand portable fire extinguishers, for underground as well as open-cast mining sites, as per the requirements.

Ansul, USA is one of the world leaders in manufacturing of fire suppression systems, Fire Protection Services, extinguishers and safety products. Founded in 1915, the company has a well-renowned customer-base. The US Government is one of the biggest customers of Ansul. The Ansul Fire School in Wisconsin, USA, is a fire school under Ansul, founded in 1940, which trains students in hands-on firefighting.

The Maco special hazard fire protection range of products include:

A-101 off-road mobile equipment fire suppression system

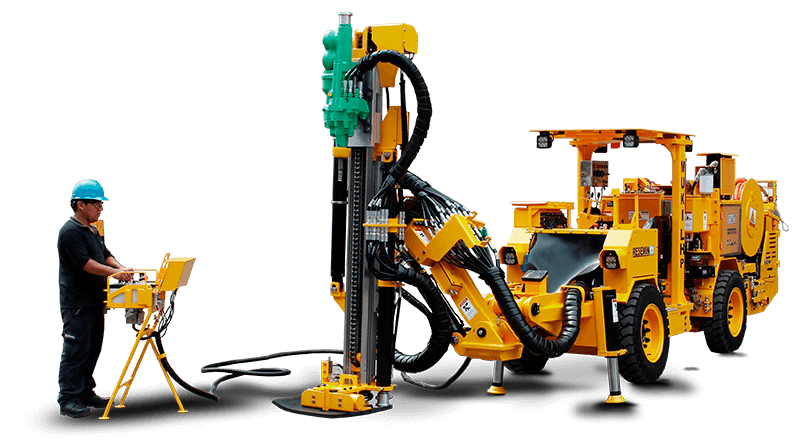

The A-101 off-road mobile equipment fire suppression system is an automatic/manual system, highly effective for a fast flame knockdown. The system provides protection for large, off-road type mining and construction equipment, as well as underground mining equipment and specialty vehicles. The brute force required to protect these heavy equipment is provided by the system, by maintaining a constant pressure throughout the entire discharge.

Eaton Airflex are the world leaders of industrial Clutches and Braking systems, required in different types of Mining Equipment, and have been the trusted original suppliers to all Global Mining Equipment OEMs’ like BEML, HEC, Marion, Bucyrus International, Caterpillar, Terex etc.

Maco is the authorized supplier of complete Clutch & Braking Solutions for Eaton Airflex. The state-of-the-art braking systems, fitted on electric motors are used for various purpose, including crowd applications, hoist applications, drag applications, swing applications and propel applications.

MineARC Systems, Australia is the global leader in the manufacture and supply of emergency safe refuge solutions for the mining, tunneling, chemical processing and disaster relief industries, with a presence in more than 40 countries worldwide. All MineARC Refuge Chambers and Safe Havens comply with the highest international regulations and recognized ‘world’s best practice’ industry guidelines. MineARC is the only refuge chambers manufacturer in the world with an ISO:9001 quality rating.

Maco provides the most advanced technology in Refuge chambers for underground mining work, with the state-of-the-art MineARC refuge chambers. These chambers are designed to provide a refuge or ‘safe haven’ for miners while working underground, in case of being trapped in a hazardous or toxic environment.

Esco Corp., A subsidiary of Weir Group Division, is one of the worlds most trusted names in manufacturing and engineering of critical equipment used in Mining and Infrastructure. It is the #1 leader of tooth systems globally and provides all kinds of expert support for its customers working with dragline and excavator buckets, crusher wear parts, shearer drums and other affiliated products used in the mining and infrastructure industry.

Maco is an authorized dealer for the sales and supply of ProFill® dragline buckets, a flagship product of ESCO Corporation. ESCO products are trusted at mines worldwide for improved productivity and safety by engineering the most efficient bucket geometry and rigging arrangement for specific applications. The ESCO ProFill® dragline buckets perform consistently across the wide variety of digging conditions in a mine plan. A proven performer, ProFill buckets fill faster, use less drag energy and deliver exceptional productivity, even in challenging above-tub applications. Each bucket is custom-engineered to pick up quicker and hang more vertically when dumping.

Every vehicle in Rock-Tech’s TITANIUM™ lineup comes with a powerful articulated platform, with each configuration specifically manufactured to speed up or improve important underground activities.

TITANIUM™ is available with three payload capacities to bring you maximum flexibility as we work together to meet the needs of your operation. Whether you’re carrying workers, freight or fuel to the face, there’s a TITANIUM™ option designed for it. Want to safely speed up shotcrete application, ANFO loading, piping, ventilation or electrical installation? There’s a TITANIUM™ configuration that is built for your purpose.

Our products and solutions deliver worker safety and productivity improvements while reducing the mines energy and greenhouse gas footprint. Maestro Digital Mine provides significant CAPEX and OPEX savings to the mines project delivery, technology (IT/OT), ventilation, energy occupational heath & safety professionals.

Our vision is to change the way that underground mines communicate and to strip out complexity in the automation sector by utilizing IIoT solutions and driving down CAPEX and OPEX. Working in partnership with the mining companies to develop solutions to real-time challenges, our digital solutions are recognized in over 38 countries and deployed globally in 150+ mines.