.svg)

FILTER BY

Need a Custom Solution?

Need a Custom Solution?

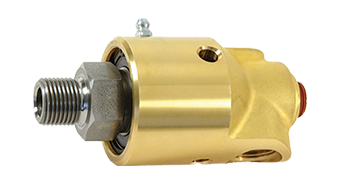

Deublin Rotary Union for Cutting Oil | Precision Fluid Transfer Solutions

Introduction

A rotary union for cutting oil is a crucial component in machining and metalworking processes, ensuring consistent fluid delivery to cutting tools for cooling, lubrication, and improved tool life. Whether used in CNC lathes, milling machines, or grinding applications, Deublin’s cutting oil rotary unions provide leak-free operation, high-speed performance, and superior durability.

Deublin’s precision-engineered rotary unions are designed to handle the high-pressure and high-speed demands of cutting oil systems. They feature advanced sealing technology to prevent leaks, corrosion-resistant materials for extended service life, and low-friction designs that reduce wear and maintenance.

By ensuring optimal cutting oil flow, these rotary unions help manufacturers reduce heat buildup, extend tool life, and achieve better surface finishes. With single-passage and multi-passage configurations, Deublin’s rotary unions are customizable to meet the specific needs of modern machining operations.

Features of Deublin Rotary Union for Cutting Oil

● Leak-Proof Sealing Technology:Advanced carbon-graphite or PTFE seals provide long-lasting, leak-free operation.

● High-Speed Compatibility: Designed for rotational speeds up to [Insert Value, e.g., 12,000 RPM], ensuring smooth cutting oil delivery.

● High-Pressure Performance: Capable of handling pressures up to [Insert Value, e.g., 5,000 PSI], making it ideal for precision machining applications.

● Durable Construction: Built from stainless steel and anodized aluminum, resistant to corrosion and wear.

● Multi-Passage Design Available: Allows simultaneous transfer of cutting oil, coolant, and air in multi-fluid applications.

● Low Friction & Energy Efficient: Reduces torque and heat buildup, extending equipment lifespan and reducing maintenance costs.

● Customizable Connection Options: Available in flanged, threaded, and quick-connect configurations for easy system integration.

Benefits

Using a rotary union for cutting oil in machining operations offers key advantages:

● Enhanced Cutting Performance: Maintains optimal lubrication and cooling, reducing tool wear.

● Extended Equipment Lifespan: Minimizes friction and heat buildup, ensuring long-term durability.

● Leak-Free Operation: Precision sealing prevents fluid loss, reducing operational costs.

● Improved Surface Finish: Consistent cutting oil flow results in smoother machining outcomes.

● Cost Efficiency: Reduces maintenance downtime and cutting oil wastage, maximizing productivity.

Applications

Deublin’s rotary union for cutting oil is widely used across industries requiring precision cutting oil transfer, including:

● CNC Machining & Metal Cutting: Ensures efficient lubrication and cooling in lathes, milling, and drilling machines.

● Grinding & Surface Finishing: Provides consistent cutting oil delivery for precision grinding applications.

● Automotive & Aerospace Manufacturing: Enhances machining accuracy in high-precision component manufacturing.

● Tool & Die Making: Maintains lubrication control for mold and die manufacturing.

● Heavy Equipment & Industrial Machinery: Optimizes cutting oil distribution in gear cutting and heavy machining.

FAQ

Q1: What is a rotary union for cutting oil used for?

A rotary union for cutting oil transfers cutting oil between a stationary and rotating system, ensuring smooth fluid delivery in machining processes

Q2: Can Deublin rotary unions handle high-pressure cutting oil?

Yes, Deublin rotary unions are designed to operate at pressures up to [Insert Value, e.g., 5,000 PSI], making them ideal for precision machining.

Q3: What industries benefit from cutting oil rotary unions?

Industries such as CNC machining, metal fabrication, automotive, aerospace, and tool making rely on cutting oil rotary unions for precision lubrication.

Q4: What maintenance is required for rotary unions?

Regular inspection of seals, bearings, and cutting oil flow paths helps maintain optimal performance and longevity.

Q5: Can Deublin rotary unions be customized?

Yes, Deublin offers custom configurations to meet specific machining and fluid transfer needs.