.svg)

FILTER BY

Need a Custom Solution?

FILTER BY

Need a Custom Solution?

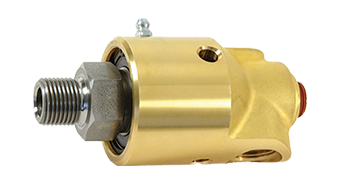

Deublin Rotary Union for Vacuum | High-Performance Sealing Solutions

Introduction

A rotary union for vacuum is an essential component for transferring air, gases, or liquids between stationary and rotating systems while maintaining a secure vacuum seal. These specialized rotary unions prevent leaks, maintain pressure integrity, and optimize the performance of vacuum-dependent industrial processes

Deublin’s rotary unions for vacuum applications are engineered to handle high-speed rotations while ensuring a tight seal under varying pressure conditions. Constructed from durable, corrosion-resistant materials and featuring precision sealing technology, these rotary unions offer long-lasting performance, minimal maintenance, and superior efficiency.

Ideal for industries such as semiconductor manufacturing, food packaging, pharmaceutical production, and scientific research, Deublin’s vacuum rotary unions ensure optimal vacuum retention, reduced downtime, and enhanced system performance. Whether your application requires a single-pass or multi-pass configuration, Deublin’s rotary unions provide customized solutions for seamless operation.

Features of Deublin Rotary Union for Vacuum

● Leak-Proof Sealing Mechanism:Advanced sealing technology ensures a secure vacuum environment and prevents leakage.

● Durable Construction: Made from high-grade stainless steel and engineered alloys to resist wear and corrosion.

● High-Speed Performance: Operates smoothly at rotational speeds up to [Insert Value, e.g., 15,000 RPM], ideal for demanding applications.

● Multi-Passage Design Available: Supports single and multi-channel configurations for complex vacuum systems

● Low Friction & Minimal Wear: Precision engineering reduces friction, extending product lifespan and reducing maintenance costs.

● Compatible with Various Fluids & Gases: Suitable for vacuum transfer of air, nitrogen, and other industrial gases

● Customizable Options: Available in multiple sizes, port configurations, and connection types for specific application needs.

Benefits

Using a rotary union for vacuum offers several advantages:

● Enhanced Vacuum Retention: Ensures an airtight seal for consistent pressure levels.

● Reduced Downtime: Long-lasting materials and advanced seals minimize maintenance needs.

● Improved Energy Efficiency: Reduces system losses and improves overall vacuum system efficiency.

● Versatile Integration: Compatible with automated systems, rotary tables, and high-speed industrial processes.

● Precision Engineering: Guarantees smooth and reliable operation for sensitive applications.

Applications

Deublin’s rotary union for vacuum is widely used across high-precision industries, including:

● Semiconductor Manufacturing: Essential for vacuum-based wafer processing and component handling.

● Food Packaging & Processing: Ensures vacuum sealing and automated handling in packaging lines

● Pharmaceutical Industry: Facilitates controlled vacuum transfer in sterile production environments.

● Aerospace & Defense: Supports vacuum testing and research in wind tunnels and space simulations.

● Scientific & Industrial Research: Used in vacuum chambers, rotary tables, and precision lab instruments.

FAQ

Q1: What is a rotary union for vacuum used for?

A rotary union for vacuum enables the transfer of gases or fluids between a stationary and rotating system while maintaining an airtight seal.

Q2: Can Deublin rotary unions handle high-speed vacuum applications?

Yes, Deublin rotary unions are designed for high-speed performance up to [Insert Value, e.g., 15,000 RPM], making them ideal for precision applications.

Q3: What industries benefit from vacuum rotary unions?

Industries such as semiconductors, food packaging, pharmaceuticals, and aerospace benefit from vacuum rotary unions for their precision and efficiency.

Q4: What maintenance is required for Deublin rotary unions?

Regular inspection of seals, bearings, and fluid pathways ensures optimal performance and extended service life.

Q5: Can Deublin rotary unions be customized?

Yes, Deublin offers customized configurations to meet specific vacuum system requirements.