.svg)

FILTER BY

Need a Custom Solution?

FILTER BY

Need a Custom Solution?

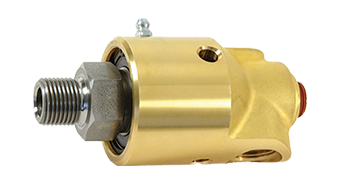

Deublin Rotary Joint for Hot Oil | High-Performance Heat Transfer

Introduction

A rotary joint for hot oil is a critical component for transferring high-temperature thermal fluids between stationary and rotating equipment in heating applications. Industries such as plastic processing, rubber manufacturing, textiles, and chemical production rely on these rotary joints to maintain precise temperature control and optimize production efficiency.

Deublin’s rotary joints for hot oil are engineered to handle extreme temperatures and pressures, ensuring safe and efficient thermal fluid circulation. Equipped with precision sealing technology and constructed from corrosion-resistant materials, these rotary joints minimize heat loss and prevent fluid leakage.

Designed for longevity and efficiency, Deublin’s rotary joints enhance heat transfer performance while reducing maintenance costs. Whether in extrusion molding, calendaring, or laminating, our rotary joints for hot oil deliver uninterrupted operation, maintaining process consistency and improving product quality.

Features of Deublin Rotary Joint for Hot Oil

● High-Temperature Resistance:Withstands extreme operating temperatures up to [Insert Value, e.g., 350°C] for efficient thermal fluid transfer.

● Leak-Proof Seal Technology: Advanced carbon-graphite seals prevent leakage, ensuring safety and minimal heat loss.

● Corrosion-Resistant Materials: Constructed from stainless steel and precision alloys to resist wear and tear from hot oil exposure.

● Optimized for High-Pressure Applications: Capable of handling pressures up to [Insert Value, e.g., 30 bar] for demanding industrial environments.

● Self-Supported Design: Eliminates the need for external bearings, reducing complexity and installation costs.

● Energy-Efficient Operation: Maximizes heat transfer efficiency while minimizing energy consumption.

● Customizable Configurations: Available in single-flow and dual-flow designs to suit different system requirements.

Benefits

Using a rotary joint for hot oil in industrial applications offers significant advantages:

● Improved Energy Efficiency: Minimizes heat loss and ensures maximum heat transfer.

● Extended Equipment Lifespan: Durable seals and corrosion-resistant materials enhance longevity.

● Cost Savings: Reduces maintenance downtime and operational costs.

● Consistent Temperature Control: Supports precise thermal regulation, improving process quality.

● Versatile Industrial Use: Compatible with various thermal fluid systems across multiple industries.

Applications

Deublin’s rotary joint for hot oil is widely used in industries requiring precise heat transfer, including:

● Plastic & Rubber Processing: Facilitates controlled heating in extrusion, calendaring, and molding operations.

● Textile Industry: Maintains consistent temperatures in dryers and heat-setting machines.

● Paper & Packaging: Ensures uniform heating in laminating and coating applications.

● Chemical & Pharmaceutical Manufacturing: Supports controlled heating in reactors and distillation units.

● Food Processing: Provides precise thermal control in baking, frying, and sterilization processes.

FAQ

Q1: What is a rotary joint for hot oil?

A rotary joint for hot oil is a device that allows thermal oil to transfer between stationary and rotating machine components, maintaining consistent heat distribution.

Q2: How does Deublin’s rotary joint improve thermal efficiency?

Deublin’s rotary joints use advanced sealing and corrosion-resistant materials to reduce heat loss and ensure precise temperature control.

Q3: What industries require rotary joints for hot oil applications?

Industries such as plastics, rubber, textiles, chemical processing, and food manufacturing rely on hot oil rotary joints for efficient heat transfer.

Q4: Can Deublin rotary joints handle high-pressure thermal fluids?

Yes, our rotary joints are designed for high-pressure systems up to [Insert Value, e.g., 30 bar], ensuring safe and reliable fluid transfer.

Q5: How often should rotary joints for hot oil be maintained?

Regular inspection of seals, bearings, and fluid pathways is recommended to maximize performance and longevity.