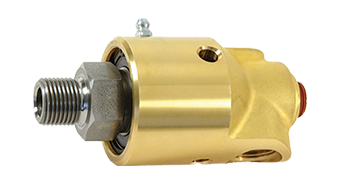

Union, G 2" RH, 2" NPT

Operating Specifications

Media

Water, Steam, Hot OilRotor Connection

G 2Housing Connection

2Hot Oil Max. Flow

390.5 l/minHot Oil Max. Pressure

6.9 barHot Oil Max. Temperature

121 °CSteam Max. Flow

1627.2 l/minSteam Max. Pressure

1 barSteam Max. Temperature

121 °CWater Max. Flow

390.5 l/minWater Max. Pressure

13.8 barWater Max. Temperature

121 °C655-500-124

- Monoflow and Duoflow Operation: This rotating union is designed to operate in both monoflow and duoflow configurations, providing versatility for a range of applications and system setups.

- Self-supported Rotating Union: Equipped with a self-supported rotating union, ensuring smooth rotation for reliable and efficient operation in various environments.

- Radial Housing Connection: Features a radial housing connection, providing stability and facilitating easy integration into different systems. This design contributes to the overall robustness of the rotating union.

- Balanced Mechanical Seals: Incorporates balanced mechanical seals for each passage, contributing to an extended lifespan and reduced torque even under challenging operating conditions. This enhances the reliability and durability of the unit.

- 3 Vent Holes: Includes three vent holes to facilitate effective venting, preventing pressure buildup within the rotating union. This contributes to the safe and efficient operation of the unit.

- Forged Brass Housing and Stainless Steel Rotor: The construction includes a forged brass housing for durability and a stainless steel rotor for corrosion resistance. This combination ensures a reliable and long-lasting rotating union.

- Special Options: Offers special options such as threaded vent holes and a low torque design, providing customization based on specific application requirements.

- Seal Combinations:

- Carbon Graphite/Bronze for Water: Suitable for water applications, providing effective sealing in water-based systems.

- Carbon Graphite/Ceramic for Hot Oil, Hot Water, and Saturated Steam: Designed to handle high-temperature conditions, making it suitable for applications involving hot oil, hot water, and saturated steam.

- Tungsten Carbide/Ceramic for Severe Conditions: Specifically designed for severe conditions such as poor water quality, providing robust sealing performance in challenging environments.

.svg)