.svg)

FILTER BY

Need a Custom Solution?

FILTER BY

FILTER BY

Need a Custom Solution?

Deublin Hydraulic Rotating Union | Reliable Fluid Power Solutions

Introduction

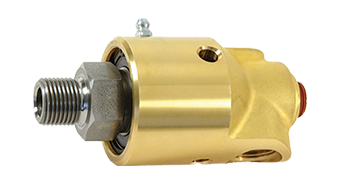

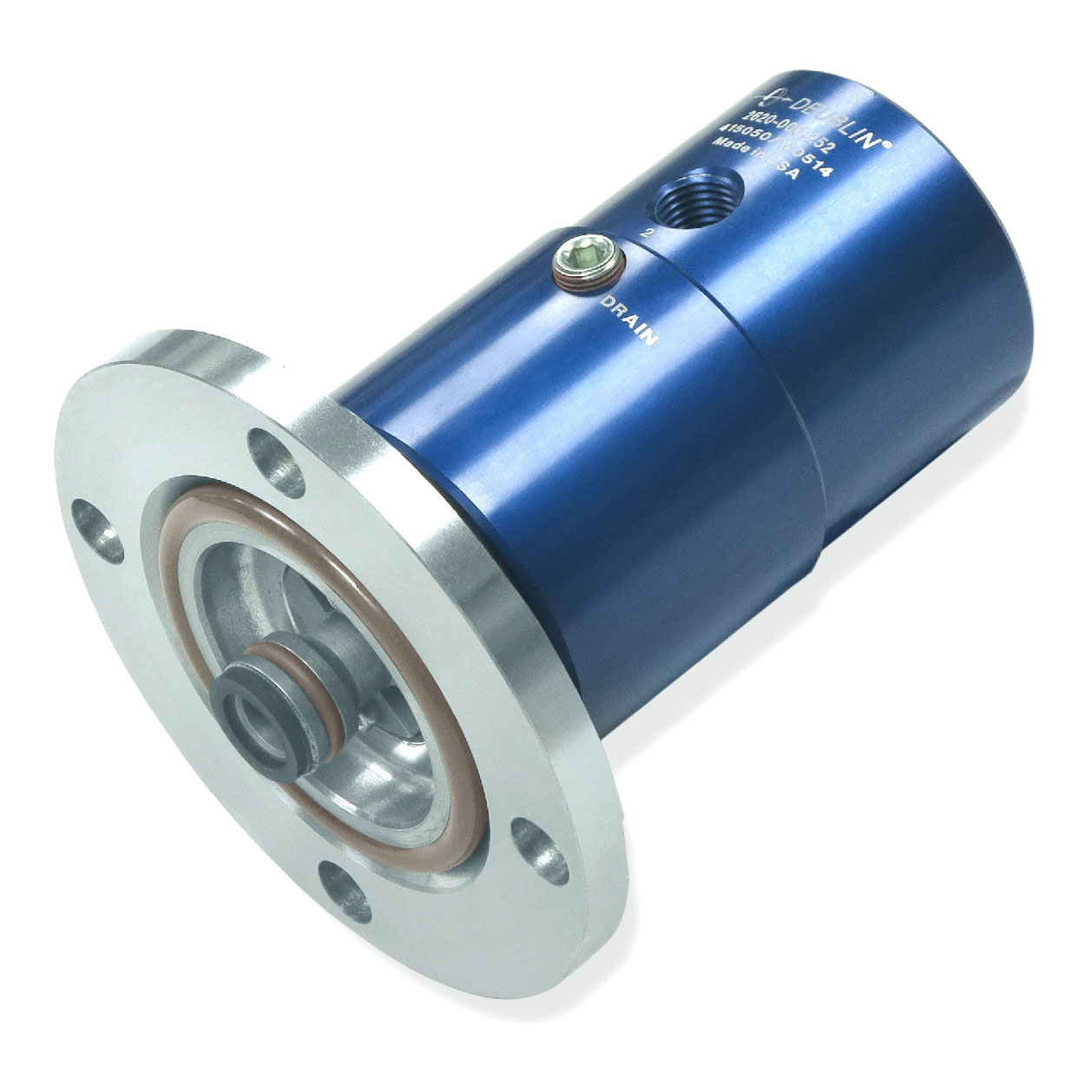

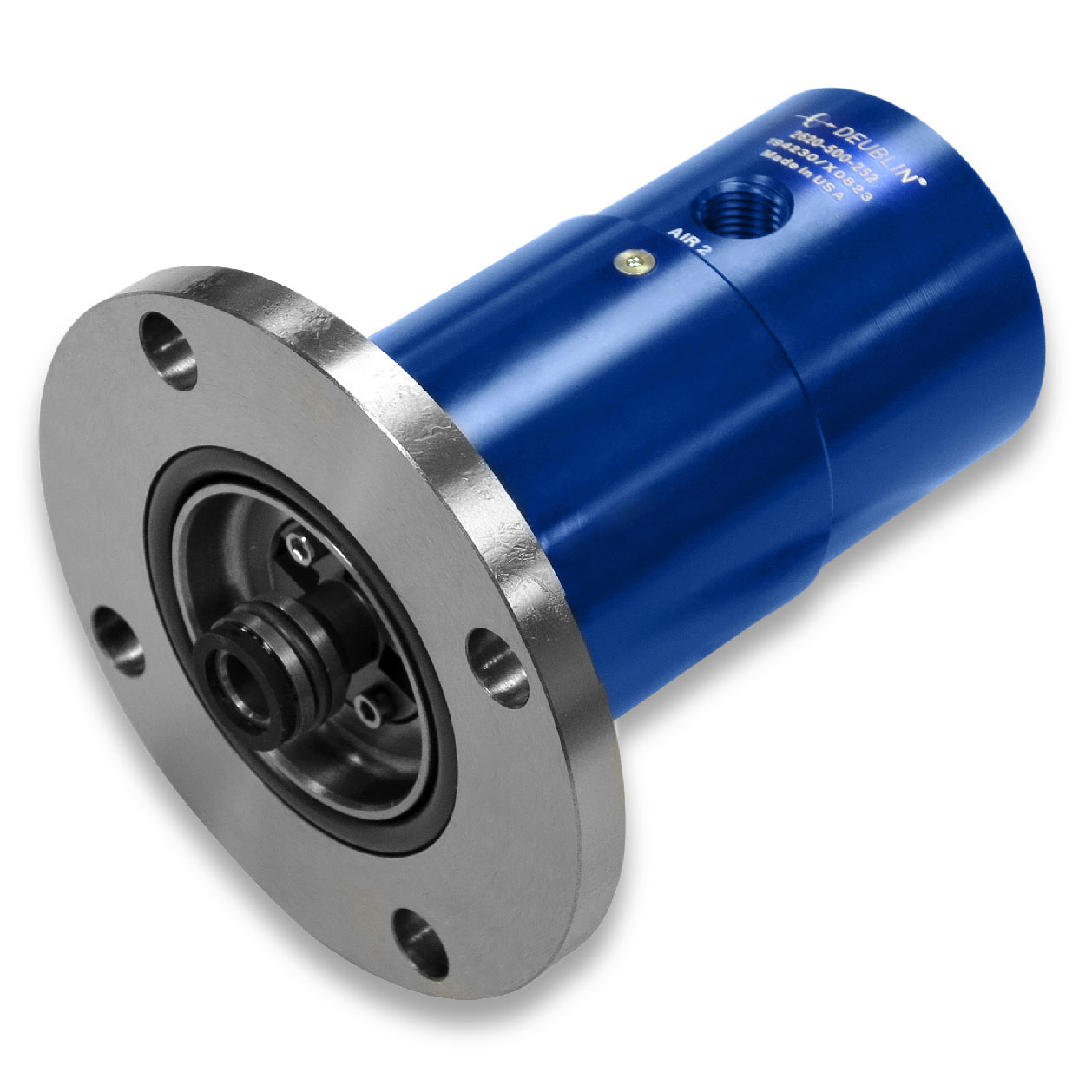

A hydraulic rotating union is a crucial component in hydraulic systems that enables the seamless transfer of pressurized hydraulic oil between stationary and rotating parts. These unions are essential for applications requiring high-speed rotation, high-pressure fluid transfer, and minimal leakage, ensuring smooth and efficient machinery operation.

Deublin’s hydraulic rotating unions are engineered with advanced sealing technology, high-strength materials, and precision machining, making them ideal for industries such as metal forming, robotics, injection molding, and heavy equipment. Designed to withstand high pressures, extreme temperatures, and harsh industrial environments, these rotary unions help maintain fluid integrity while reducing maintenance costs.

With single-passage and multi-passage configurations, Deublin’s hydraulic rotating unions allow for simultaneous transfer of hydraulic fluid, coolant, and other media, offering maximum versatility and efficiency. Whether in offshore drilling, hydraulic presses, or automated machinery, Deublin provides customized solutions tailored to industrial demands.

Features of Deublin Hydraulic Rotating Union

● High-Pressure Capability:Handles pressures up to [Insert Value, e.g., 5000 PSI], making it ideal for demanding hydraulic applications.

● Leak-Proof Sealing System: Advanced carbon-graphite or PTFE seals ensure a tight seal, reducing fluid loss and maintenance costs.

● High-Speed Performance: Operates at rotational speeds up to [Insert Value, e.g., 10,000 RPM] for precision motion control.

● Durable Construction: Made from hardened stainless steel and high-strength alloys to withstand extreme operating conditions.

● Multi-Passage Configuration Available: Supports simultaneous transfer of multiple fluids, enhancing machine efficiency.

● Corrosion & Wear Resistance: Special coatings and materials protect against corrosion, heat, and abrasive wear.

● Customizable Connection Types: Available in flanged, threaded, and quick-connect options for easy integration into hydraulic systems.

Benefits

Using a hydraulic rotating union in hydraulic systems provides significant advantages:

● Optimized Hydraulic Efficiency: Maintains consistent fluid pressure for uninterrupted operation.

● Extended Equipment Lifespan: Reduces friction, wear, and maintenance downtime.

● Leak-Free Operation: Precision-engineered seals prevent fluid loss, improving system efficiency.

● Versatile Integration: Compatible with multi-fluid transfer systems, enabling custom applications.

● Cost Savings: Reduces maintenance and operational costs with its durable and efficient design.

Applications

Deublin’s hydraulic rotating union is widely used in industries that require efficient high-pressure fluid transfer, including:

● Metal Forming & Press Machines: Ensures precise hydraulic control in hydraulic presses and forging machines.

● Injection Molding & Plastics: Transfers hydraulic power to robotic arms and rotary actuators, ensuring smooth motion.

● Robotics & Automation: Transfers hydraulic power to robotic arms and rotary actuators, ensuring smooth motion.

● Oil & Gas Industry: Used in offshore drilling, hydraulic control valves, and wellhead equipment.

● Heavy Equipment & Construction: Supports vacuum testing and research in wind tunnels and space simulations.

FAQ

Q1: What is a hydraulic rotating union used for?

A hydraulic rotating union allows the transfer of hydraulic oil between a stationary and rotating system, ensuring fluid continuity and pressure control.

Q2: Can Deublin rotary unions handle multi-fluid transfer?

Yes, Deublin’s multi-passage hydraulic unions can transfer hydraulic oil, coolant, and compressed air simultaneously.

Q3: What industries benefit from hydraulic rotating unions?

Industries such as metal forming, robotics, plastics, oil & gas, and construction use hydraulic rotating unions for efficient fluid control.

Q4: What maintenance is required for hydraulic rotating unions?

Regular inspection of seals, bearings, and pressure levels ensures longevity and optimal performance.

Q5: Can Deublin hydraulic unions be customized?

Yes, Deublin provides custom configurations to meet specific hydraulic system requirements.