.svg)

FILTER BY

FILTER BY

Need a Custom Solution?

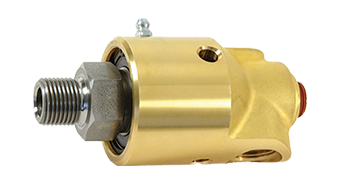

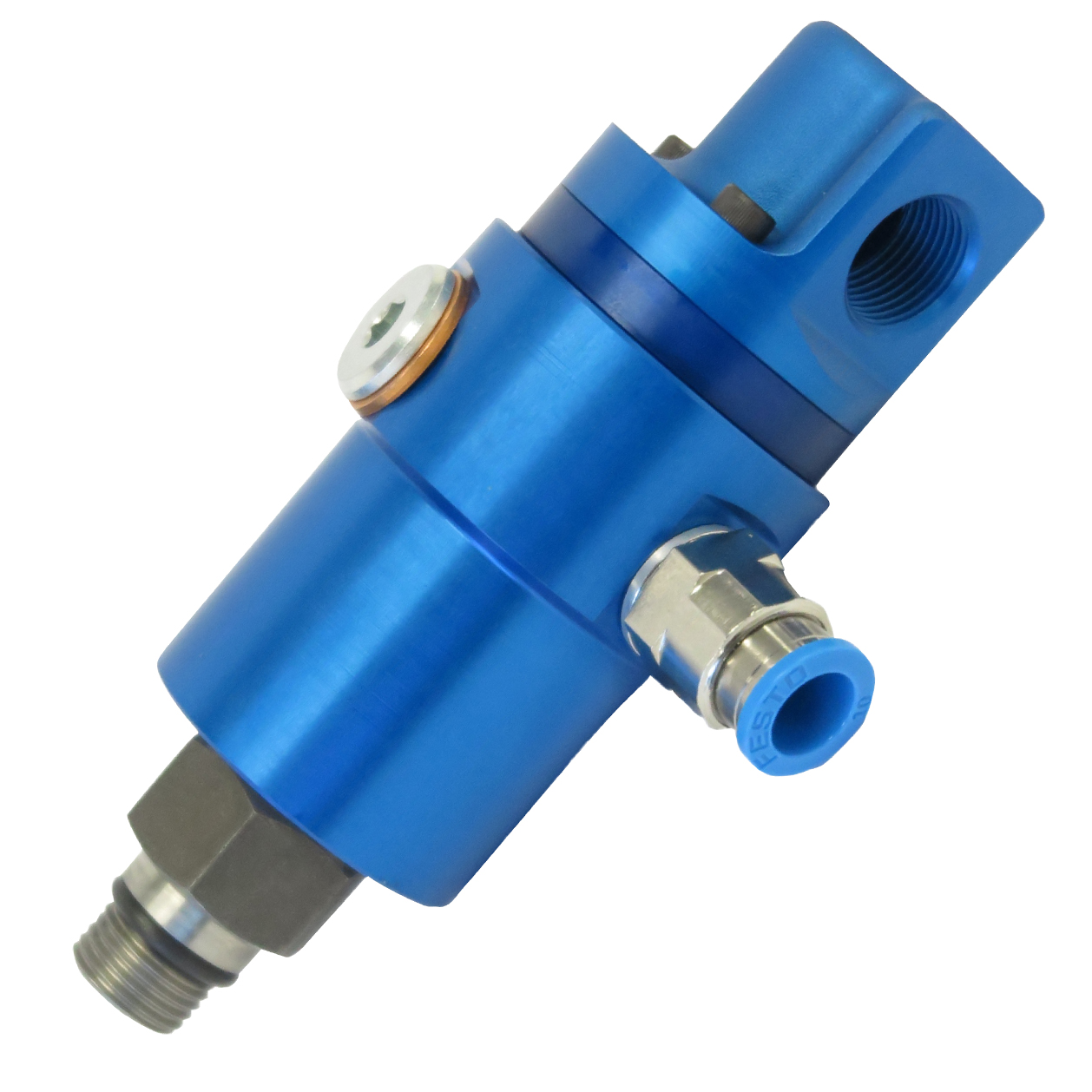

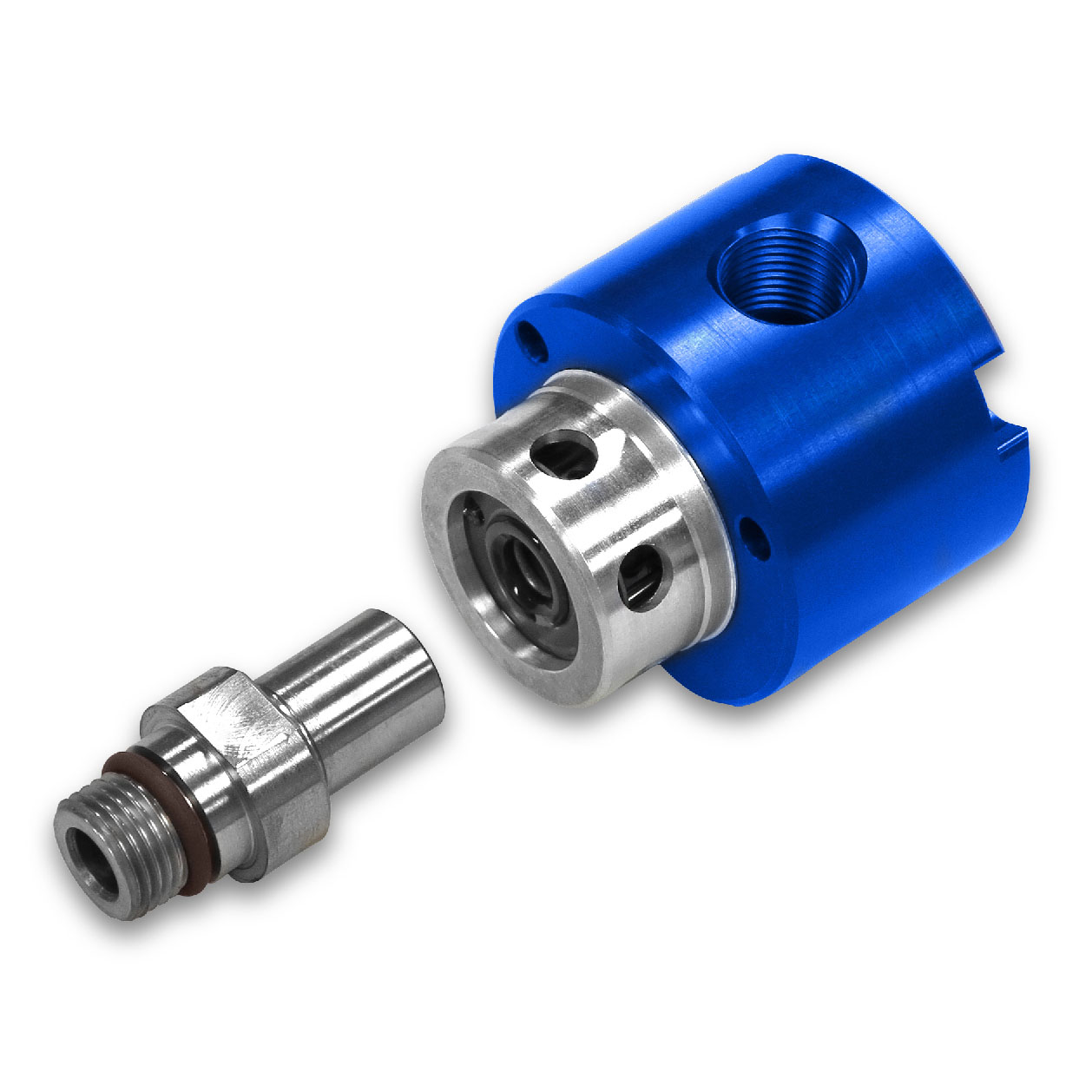

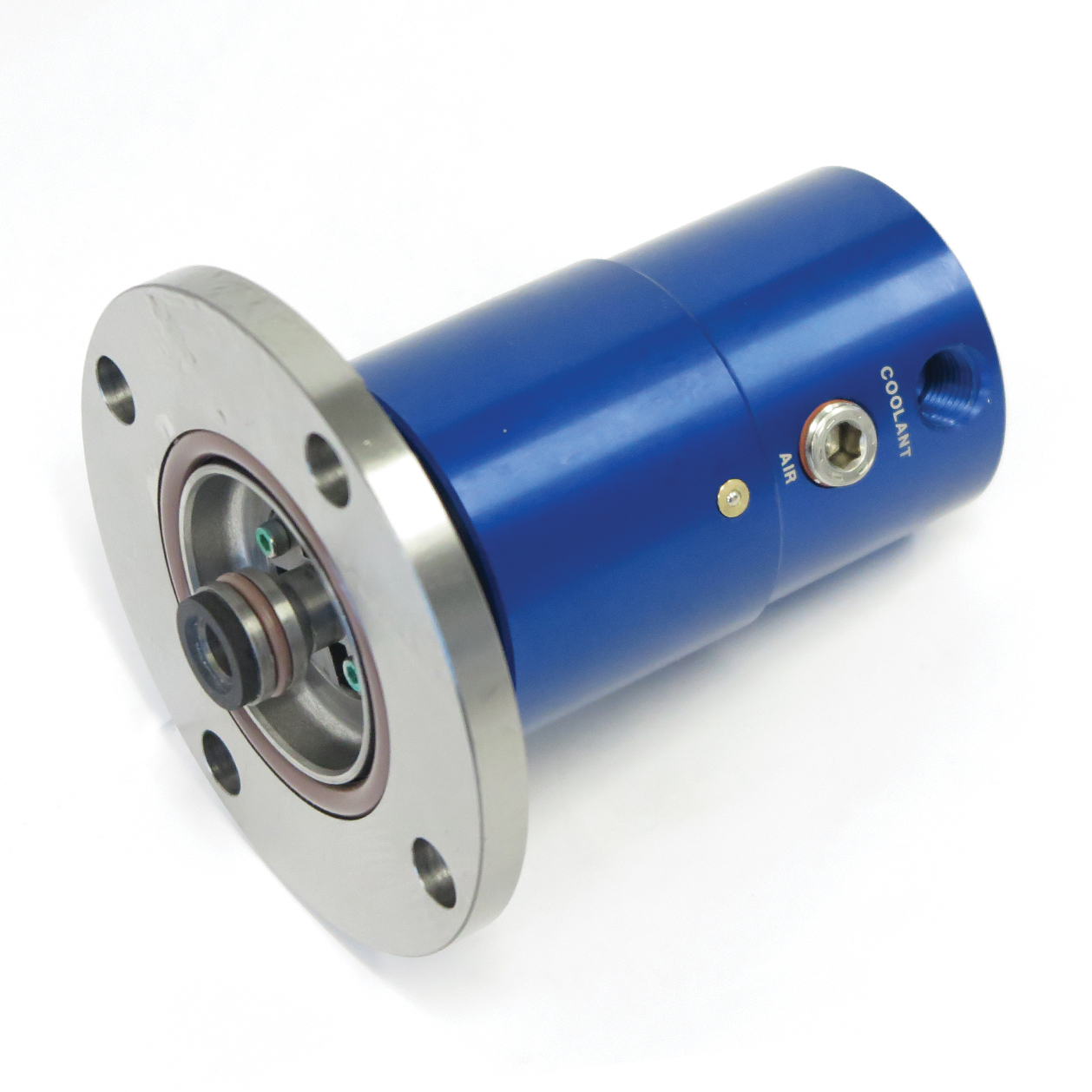

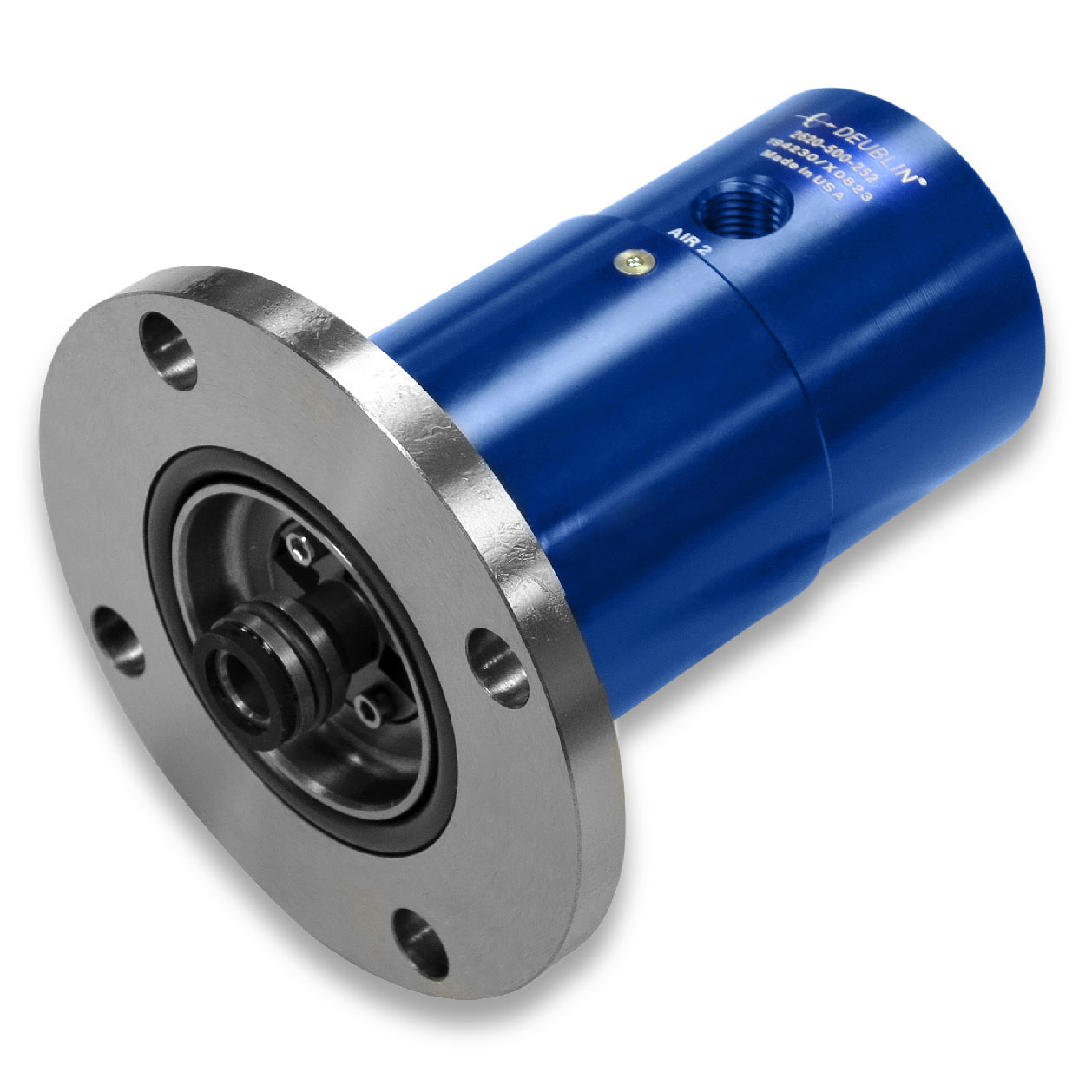

Coolant Rotary Union | Precision Fluid Transfer Solutions

Introduction

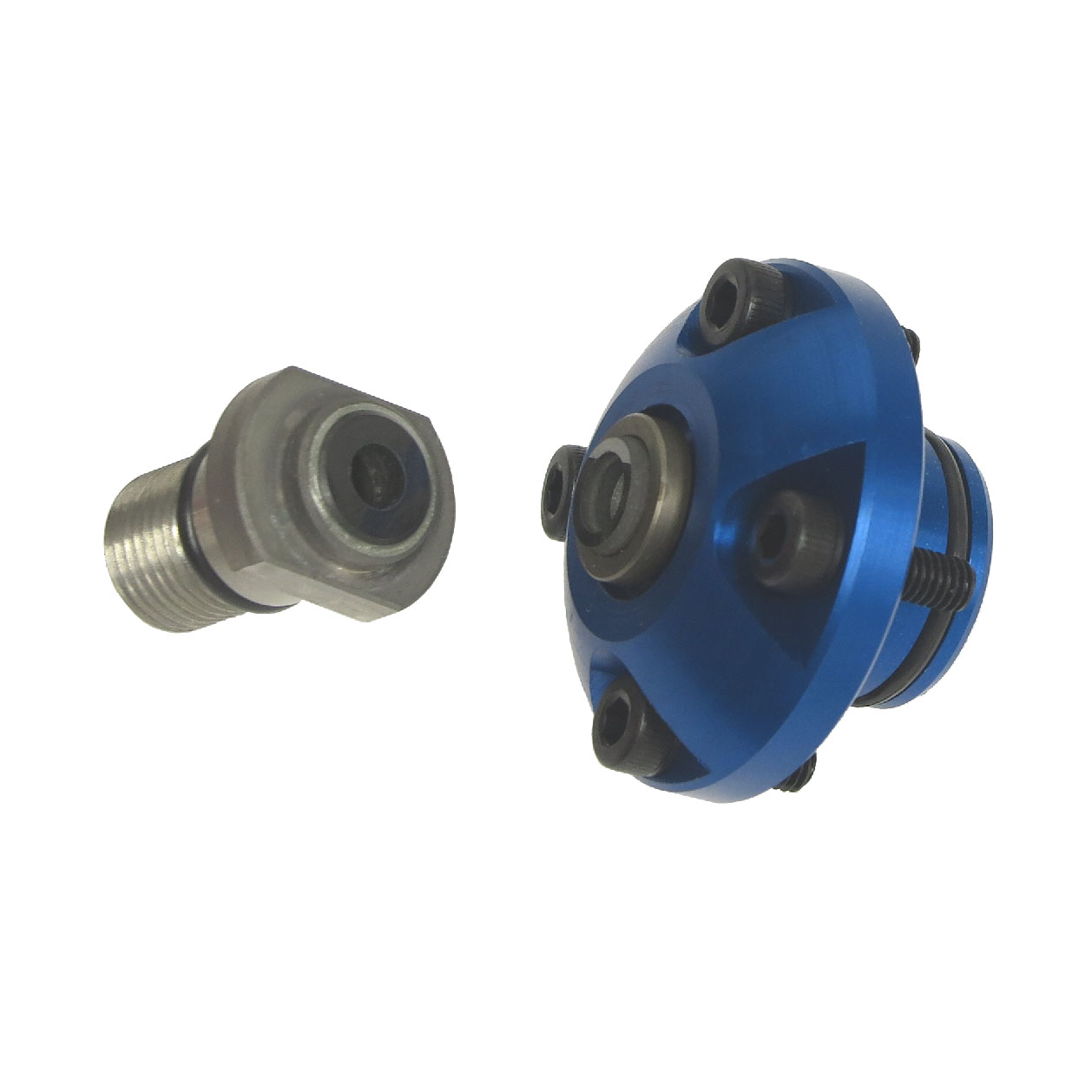

A coolant rotary union is a specialized mechanical device engineered to transfer coolant, air, or hydraulic fluid between stationary and rotating components in industrial machinery. These unions play a crucial role in high-precision machining processes, ensuring seamless coolant flow while reducing wear and tear on equipment.

Designed for durability and efficiency, coolant rotary unions are indispensable in CNC machining, metal cutting, and other high-speed manufacturing applications. At Maco Corporation, we offer a wide range of coolant rotary unions built with advanced sealing technology, corrosion-resistant materials, and precision engineering to meet the rigorous demands of modern industrial processes. Whether your requirement is for high-speed or high-pressure applications, our solutions deliver superior performance and extended service life.

Features of Coolant Rotary Unions

Advanced Sealing Mechanism: Reduces leakage and minimizes maintenance needs, ensuring consistent performance.

High-Speed Capability: Operates seamlessly at rotational speeds of up to [Insert Value, e.g., 10,000 RPM].

Pressure-Resistant Design: Handles pressures up to [Insert Value, e.g., 100 bar], ideal for high-pressure coolant systems.

Corrosion-Resistant Materials: Made with stainless steel and other robust materials to resist wear in harsh environments.

Compact and Lightweight: Designed for space-saving installation without compromising performance.

Wide Temperature Range: Operates efficiently across temperatures ranging from [Insert Range].

Customizable Configurations: Available in multiple sizes and configurations to suit specific industrial needs.

Benefits

Increased Productivity: Ensures uninterrupted fluid transfer, reducing machine idling.

Enhanced Equipment Longevity: Minimizes wear on seals and bearings, extending the life of your machinery.

Cost Savings: Reduces maintenance frequency and associated costs.

Versatility: Suitable for various machining processes and compatible with a range of fluids.

Precision Performance: Maintains accurate fluid control even under demanding conditions.

Applications

CNC Machining: For high-precision coolant flow during metal cutting and milling.

Automotive Manufacturing: Ensures efficient cooling in machining systems.

Aerospace Industry: Supports high-performance drilling and grinding operations.

Hydraulic Systems: Facilitates fluid transfer in rotating hydraulic setups.

Metal Forming: Enhances cooling in extrusion and metal shaping processes.

FAQ

What is a coolant rotary union, and how does it work?

A coolant rotary union transfers fluids like coolant or oil between stationary and rotating machine components using advanced sealing systems to prevent leakage.

Can coolant rotary unions handle high-pressure fluids?

Yes, our coolant rotary unions are designed to handle pressures up to [Insert Value, e.g., 100 bar], making them suitable for high-performance applications.

What maintenance does a coolant rotary union require?

Regular checks on seals, bearings, and lubrication ensure optimal performance and extended lifespan.

Are these unions compatible with all types of coolants?

Yes, they are compatible with water-based coolants, oils, and other industrial fluids.

How do I choose the right rotary union for my application?

Consider factors like rotational speed, pressure, fluid type, and port size. Our experts can guide you in selecting the best solution.