.svg)

FILTER BY

Need a Custom Solution?

FILTER BY

Need a Custom Solution?

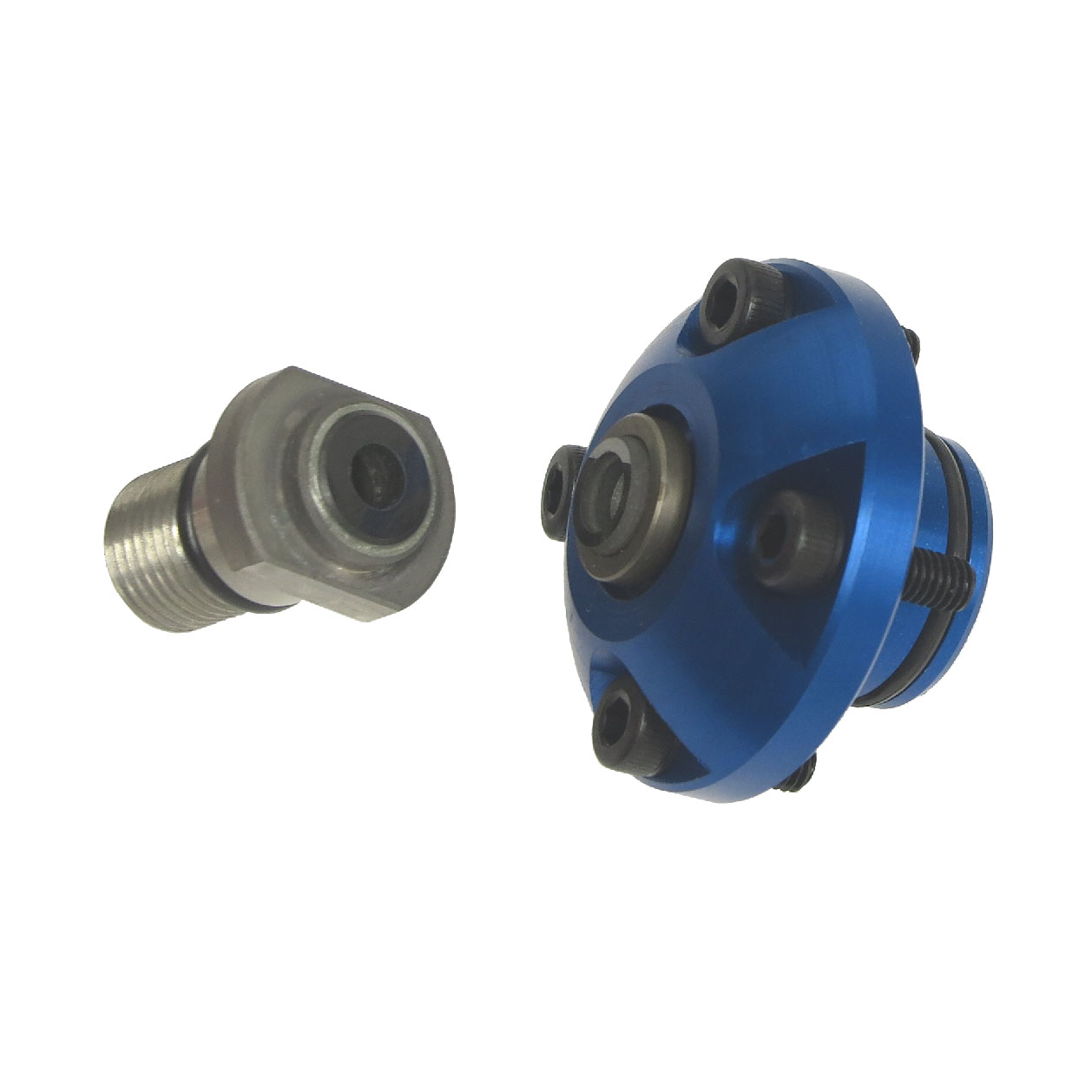

Deublin Rotating Joint MQL | High-Precision Minimum Quantity Lubrication

Introduction

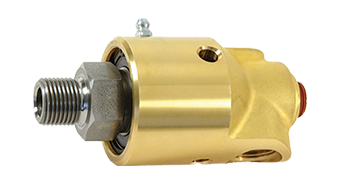

Deublin’s rotating joint for Minimum Quantity Lubrication (MQL) is a cutting-edge solution for precision machining, minimizing coolant waste while maximizing tool life and efficiency. MQL technology delivers a fine mist of lubricant directly to the cutting zone, reducing friction, heat, and material wear.

The Deublin rotating joint is engineered for seamless integration into MQL systems, ensuring leak-proof operation and consistent lubricant distribution. With its robust construction and advanced sealing mechanisms, it is ideal for high-speed machining centers, CNC lathes, and milling applications. The combination of high-speed capabilities and reliable lubrication delivery helps manufacturers achieve superior surface finishes, reduced cycle times, and lower operational costs.

Designed for sustainability, this rotating joint significantly reduces coolant consumption, making it an environmentally friendly choice for modern machining processes. Whether used in the automotive, aerospace, or general metalworking industries, the Deublin rotating joint MQL ensures precision, durability, and cost savings.

Features of Deublin Rotating Joint MQL

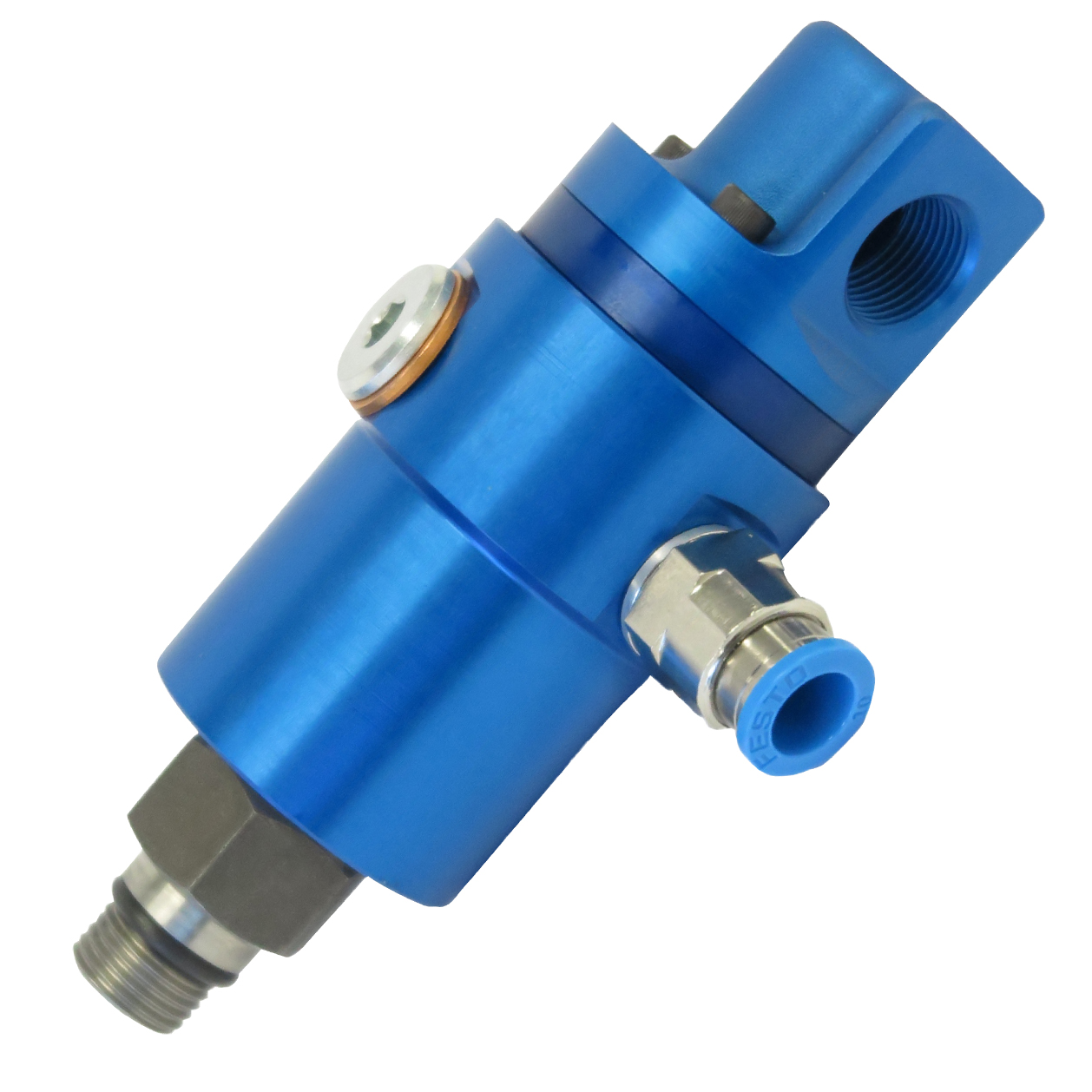

● Optimized for MQL Applications: Ensures precise lubricant delivery, reducing fluid waste and enhancing cutting efficiency.

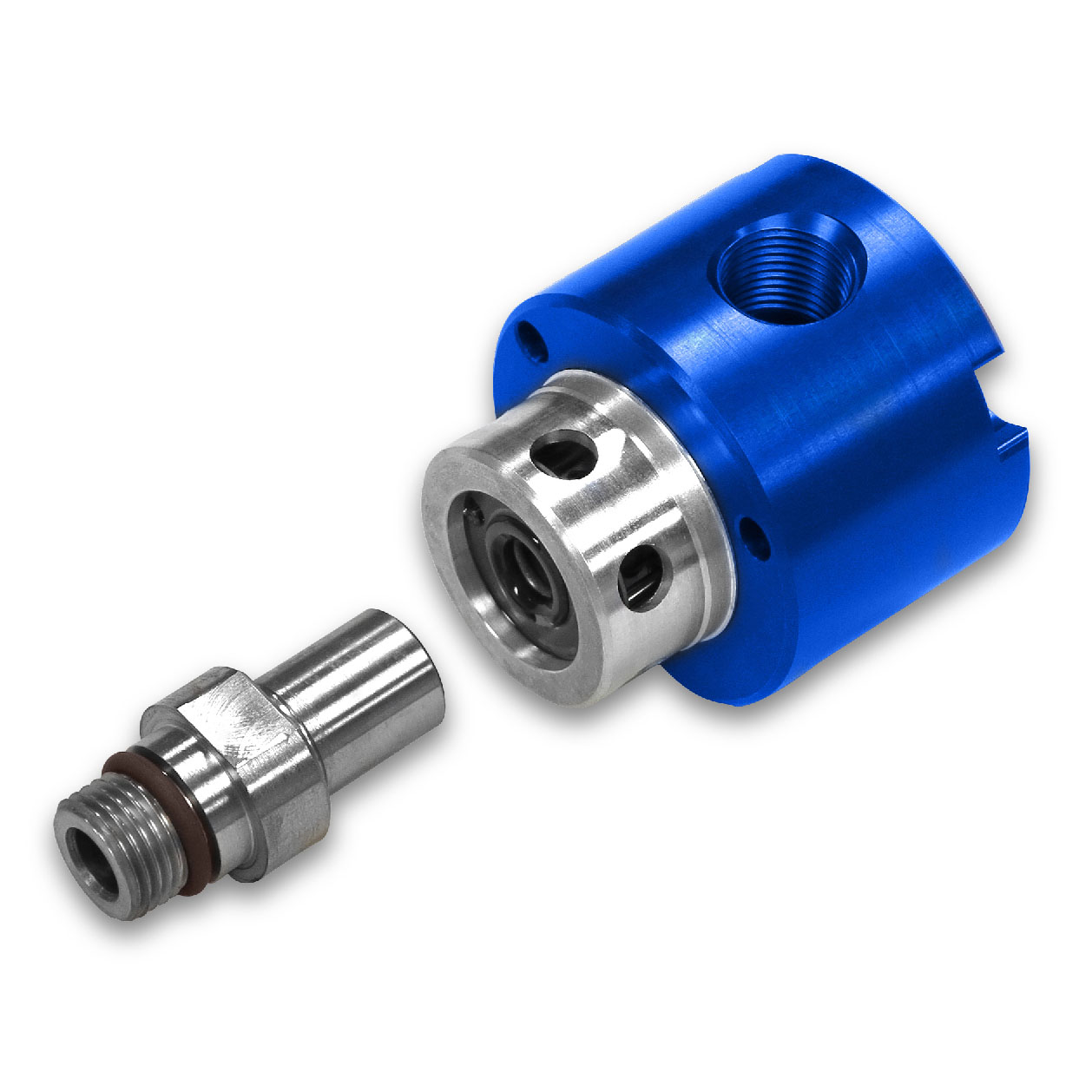

● Advanced Sealing Technology: Features innovative seals that prevent leaks and ensure long-lasting performance.

● High-Speed Compatibility: Designed to function at speeds of up to [Insert Value, e.g., 20,000 RPM], making it ideal for high-performance machining.

● Durable Construction: Built with corrosion-resistant materials, ensuring extended service life in demanding environments.

● Low Maintenance Requirements: Reduces downtime with self-lubricating seals and minimal wear components.

● Compact & Lightweight Design: Easy to install in tight machining setups without compromising performance.

● Energy & Cost Efficient: Reduces coolant and lubricant consumption, lowering operational expenses.

Benefits

The Deublin rotating joint MQL offers several advantages:

● Increased Tool Life: Reduces heat and friction, prolonging the lifespan of cutting tools.

● Eco-Friendly Machining: Minimizes coolant usage, contributing to a sustainable manufacturing process.

● Superior Surface Finish: Delivers consistent lubrication for improved machining precision.

● Lower Operational Costs Decreases coolant and maintenance expenses.

● High-Speed Performance: Optimized for fast-moving spindles and rotary applications.

Applications

The Deublin rotating joint is widely used in industries that require precision machining with MQL technology:

● Automotive Industry: Enhances metal cutting and drilling operations with minimal lubrication.

● Aerospace Manufacturing: Ensures precise machining of lightweight materials like aluminum and titanium.

● CNC Machining Centers: Delivers efficient lubrication in high-speed milling and turning applications.

● Metalworking & Fabrication: Reduces fluid waste and increases tool efficiency.

● Medical Device Manufacturing: Supports precision machining of surgical instruments and implants.

FAQ

Q1: What is a rotating joint used for?

A rotating joint is a mechanical device that enables the transfer of fluid, such as lubricant or coolant, between stationary and rotating machine components.

Q2: Why is the Deublin rotating joint ideal for MQL applications?

It is specifically designed for Minimum Quantity Lubrication, delivering precise fluid control while minimizing waste.

Q3: How does MQL technology improve machining performance?

MQL reduces friction, heat, and tool wear, leading to longer tool life and improved surface finishes.

Q4: What industries benefit from using a rotating joint for MQL?

Industries such as automotive, aerospace, CNC machining, and metal fabrication benefit from MQL-based rotating joints.

Q5: What is the maximum operating speed of the Deublin rotating joint?

It can handle speeds up to [Insert Value, e.g., 20,000 RPM], making it suitable for high-speed machining applications.