Safety has to be the top priority for any building, and it only gets more important when we’re talking about large industrial premises that are already easily susceptible to fire and workplace hazards. For industrial buildings like warehouses, safety means investing in emergency lighting, intruder safety, carbon monoxide detectors, and especially fire protection systems like smoke alarms, fire extinguishers, and other items.

Why Is It Important to Invest In Workplace Safety?

There are many reasons to invest in workplace safety. With the right investments into the right safety measures, you’re able to save thousands on insurance payments in the long run. Ensuring your industrial premises can function as needed also means that there’s minimal impact on your day-to-day operations, so your business runs smoothly and without problems.

There are many reasons to invest in workplace safety. With the right investments into the right safety measures, you’re able to save thousands on insurance payments in the long run. Ensuring your industrial premises can function as needed also means that there’s minimal impact on your day-to-day operations, so your business runs smoothly and without problems.

However, the biggest benefit is saving human lives. There’s nothing worse for your business than human lives being lost on your premises, and that’s why companies around the globe invest in preventative measures to keep their employees safe.

What’s Considered Best Practices for Preventative Safety?

To further ensure that your industrial premises are as safe as can be, here’s a breakdown of what’s considered best practices for preventative safety:

1. Early Reporting

Your staff should receive training, and further encouragement, to report any concerns related to safety so that the proper measures can be taken in time. Everybody from managers to everyday labor should receive this training. However, to ensure workplace relationships aren’t damaged, there should be an independent forum for reporting safety concerns, possibly through anonymous forms.

2. Maintaining Safety Protocol Checklists

To further amp up your preventative safety procedures, you should design safety protocol checklists for your buildings. These should be comprehensive so that as long as the items on them are monitored closely, the chances of workplace mishaps and accidents occurring are minimized. Safety inspection forms and incident reports are two commonly seen types of safety protocol checklists.

3. Keeping Safety Gear On Hand

Wearing safety gear when appropriate should be an ironclad rule for workers on your industrial premises. Especially when working with heavy tools or complex machinery, their operators and users must wear their safety gear to reduce chances of significant injuries from accidents.

4. Creating A Safety Culture

Cultivating a culture where safety is prioritized is very important for your industrial building. This isn’t as hard as it sounds either, and mostly consists of arranging seminars, fire drills, and the proper training for your employees.

5. Installing Emergency Lights and Generators

The proper lighting is vital to ensuring safety in a workplace. A natural disaster or even a simple power outage could cause the lights to go out and potentially endanger the lives of employees. That’s why both emergency generators and lights are some of the most important measures for preventative safety. If your building has a medical bay, having a backup generator will definitely save lives!

Finding the Right Workplace Safety Measures with Maco Corp: The Takeaway

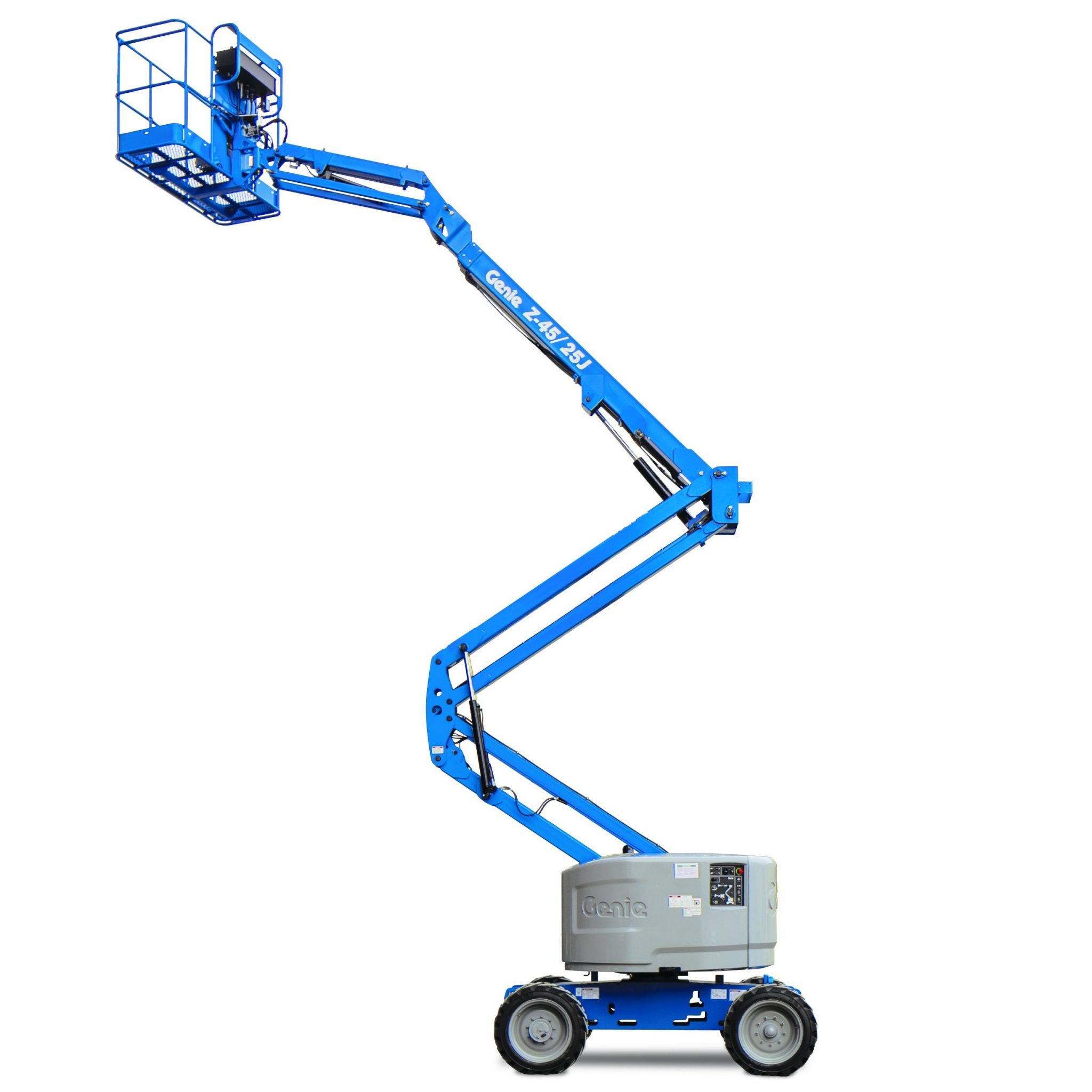

In order to keep the safety standards high, the workplace should be well equipped with equipments that provides access to hazardous sections of the workplace, where boom lifts come into play. At Maco Corporation, we are the leading authorized distributor of Genie Access Lifts. Check out their website for more information, or mail us your queries at info@macocorporation.com.

Find the Scissor Lift at best price in India.