Do you have any doubts about the rotary joint seal kit?

In this blog post, we will delve into the world of rotary joint seal kits, exploring their significance, components, maintenance, and the key role they play in keeping operations running seamlessly.

In the realm of industrial machinery, rotary joints play a crucial role in facilitating the smooth transfer of fluids and gases between stationary and rotating parts. These joints are found in a variety of applications, from manufacturing processes to heavy machinery.

One integral component that ensures the optimal performance of rotary joints is the seal kit.

Understanding Rotary Joints and Their Functionality

Before we delve into the details of rotary joint seal kits, it’s essential to grasp the basic functionality of rotary joints. These components are designed to transfer fluids or gases between a stationary and a rotating part of a machine.

Rotary joints are commonly used in applications like steam heating, hydraulic systems, and various manufacturing processes where the transfer of media between rotating and stationary elements is essential.

The Role of Rotary Joint Seal Kits

Rotary joint seal kits are critical elements in maintaining the efficiency and longevity of rotary joints. These kits include wearing parts such as seals, gaskets, and ball bearings that prevent the leakage of fluids or gases from the joint. The primary functions of rotary joint seal kits include:

Leak Prevention

The seals in the kit create a tight barrier against fluid or gas leakage, ensuring that the transfer occurs only where intended.

Contamination Protection

Rotary joint seal kits also safeguard the joint from external contaminants such as dust, dirt, and moisture, which could otherwise compromise the performance of the joint.

Temperature and Pressure Resistance

The materials used in seal kits are chosen for their ability to withstand specific temperature and pressure conditions, ensuring that the rotary joint operates optimally in diverse environments.

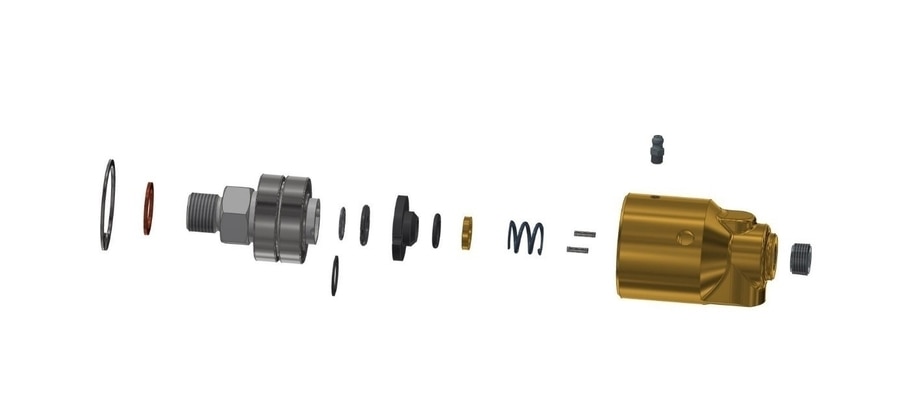

Components of a Rotary Joint Seal Kit

A typical rotary joint seal kit comprises several components, each serving a specific purpose:

Seals

O-rings, lip seals, and other types of seals create a tight barrier against fluid or gas leakage.

Gaskets

These components provide an additional layer of protection and help maintain a secure seal between the stationary and rotating parts.

Bearings

Some rotary joint seal kits include bearings that facilitate smooth rotation and reduce friction between moving parts.

Retaining Rings

These are used to secure seals and other components in place, preventing them from dislodging during operation.

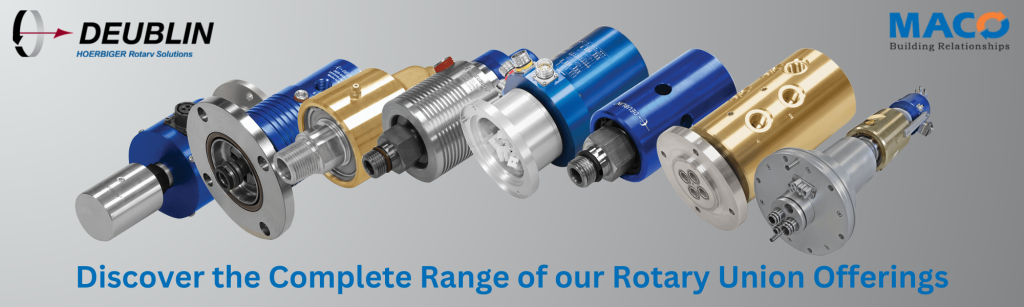

Deublin’s Contribution: Repair Kits and Specialized Tools

- Rotating unions wear out over time, just like other machines. Deublin, the most trusted company rotary union company, makes repair kits for many of their unions. These kits have everything you need to fix them yourself.

- Deublin also provides special tools and instructions to help you do the job right. This means your equipment lasts longer.

- Deublin has been making reliable rotating unions for many years. They actively engage with their customers, attentively consider feedback, and continuously enhance their products based on valuable insights.

Here are some tips for getting the most out of your Deublin unions:

- Use the right seals for the job. Different liquids and gases require different seals.

- Keep your unions clean. The presence of dirt and grime has the potential to reduce their lifespan.

By following these tips, you can get the most out of your DEUBLIN rotating unions and keep your equipment running smoothly.

Frequently Asked Questions

What is a rotary joint seal kit, and why is it important?

A rotary joint seal kit is a collection of components, including seals, gaskets, bearings, and retaining rings, designed to maintain the efficiency and longevity of rotary joints. It prevents leakage of fluids or gases and protects the joint from contaminants.

How do rotary joints function, and where are they commonly used?

Rotary joints transfer fluids or gases between stationary and rotating parts in machinery. They find applications in steam heating, hydraulic systems, and various manufacturing processes where media transfer between rotating and stationary elements is essential.

Why do rotary joints have a limited service life, and what are wearing parts?

Rotary joints have a finite service life due to wearing parts such as seals, gaskets, and ball bearings. These components experience wear and tear during operation, necessitating regular maintenance and potential replacement.

What role do repair kits play in maintaining rotary joints, and where can they be obtained?

Repair kits include essential components for comprehensive repairs of rotary joints, offering seals, gaskets, bearings, and more. Maco Corporation offers repair kits for various models of Deublin rotating unions.

Why is it crucial to use specialized tools and repair instructions for rotary joint repairs?

Specialized tools and repair instructions provided by DEUBLIN ensure that maintenance teams can efficiently and effectively repair rotary joints, minimizing downtime and extending the service life of these components.

How does DEUBLIN contribute to the reliability of rotating unions?

DEUBLIN’s extensive experience, ongoing customer collaboration, and commitment to innovation position them as a reliable source for high-performance rotating unions. Their expertise ensures products that meet and exceed industry standards.

Why are matching sealing elements to the respective medium essential in concrete applications?

In concrete applications, DEUBLIN emphasizes the importance of tailored sealing solutions. Matching sealing elements to the specific medium ensures optimal performance, contributing to maximum service life in diverse industrial settings.

What guidelines should be followed to maintain cleanliness when storing and handling rotary unions?

Adhering to guidelines issued by DEUBLIN regarding cleanliness on the customer’s premises is essential. Maintaining cleanliness during storage and handling ensures that rotary joints remain free from contaminants, contributing to extended durability and reliability.

How does DEUBLIN ensure the highest level of reliability in their Rotating Unions?

DEUBLIN leverages many years of experience, ongoing collaboration with customers, and a commitment to sourcing innovations in-house and from suppliers. This approach places them in a position to provide reliable Rotating Unions at the highest level.

What benefits can industries expect by incorporating DEUBLIN’s repair kits, tools, and guidelines?

By utilizing DEUBLIN’s repair kits, tools, and adhering to guidelines, industries can optimize the longevity of their rotary joints, minimize downtime, and maintain uninterrupted productivity in their operations.

Conclusion

In conclusion, rotary joint seal kits are indispensable components that contribute to the reliable and efficient operation of rotary joints in various industrial applications. Understanding their role, components, and the importance of regular maintenance is crucial for ensuring the longevity and optimal performance of these vital elements in industrial machinery. Deublin’s contribution with specialized repair kits, tools, and tailored sealing solutions further enhances the capabilities of rotary joints, making them a reliable choice for industries aiming to maximize the efficiency and service life of their equipment.

You can contact Maco Corporation, an exclusive partner for Deublin Products in India, for any queries related to Seal Kit or Rotary Union in general, through mail, phone, or online enquiry. Our product managers will be happy to help you.