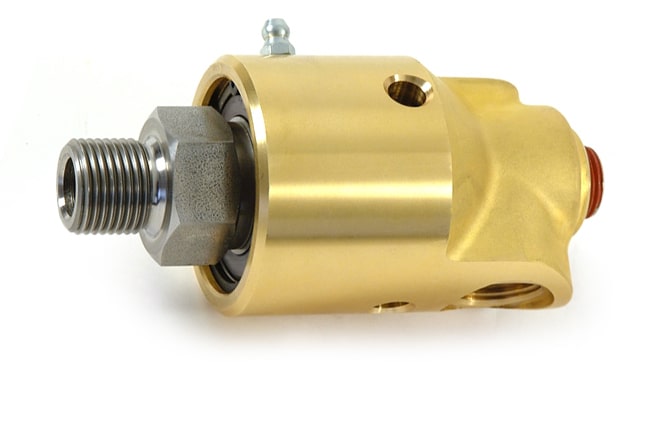

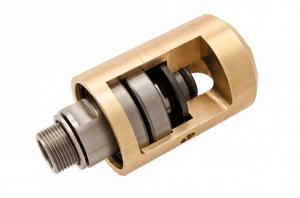

Rotary joints are widely used in different industries, like- mining, paper miles, plastic, textile, printing, glass, medicine, washing, electric power, food, and so on. This tool is excellent in transferring fluid from a fixed part of a machine to a moving part and vice versa. The fluid can be in liquid form, gaseous, under force, or under vacuum. A rotary union is made with a body, one or more seals, one or more bearings, and a shaft. Rotary unions are designed to connect motion applications to a fixed place of coolant, thermal oil, air, hydraulic oil, or other media. Rotary union is also known as a rotary distributor and rotary joint. If you are on the way to choosing a rotary union for your site, then here are things that you should know—

How to choose the best rotary union?

The act of choosing the best rotary union depends on different parameters. The first thing to consider is the media, the union will be used for. A rotary union is used for different media, like- vacuum, oil, gas, coolant, air, and steam. The fitting material should have the capability to tolerate the temperature and nature of the media.

The number of passages required for the speed and pressure in your installation, and the operating temperature will define the size of the rotary union. You will need a rotary union attached with a slip ring if you transmit an electric signal in your transmission.

How to experience the optimum performance of a rotary union?

While installing a rotary union on your site, expecting the best result from the tool is the final intention. And the result depends on various things. Though manufacturers are continuously launching the best rotary union, which poses the optimum proficiency and support, it is essential to consider a few things to enjoy the most of the rotary union.

After installing the rotary union, the slip ring is the primary wearing part. Changing the seal ring is essential when maximum wear has been achieved. Remember, it is a must-to-do job otherwise, the rotary union will be damaged.

Other characteristics to know before selecting a rotary union:

Apart from the mentioned facts, it is important to know the material of the rotary union. A rotary union can be made with different materials. Aluminum, brass, steel, cast iron even bronze can be used in manufacturing a rotary union. You have to consider the material according to the fluid type that you are going to transfer through the media. These days, the manufacturer offers custom rotary union as well.

How to calculate the dimension of your rotary union?

You can find rotary unions of different sizes. The following characteristics determine the dimensions—

- The rational speed and direction of the tool.

- The operating pressure of the rotary union.

- The nominal diameter of the tool.

- The operating and ambient temperature of the union.

Hope the mentioned points will help you in finding the best rotary union for your site. At MACO, you will have a wide range of rotary unions to choose from. It is a top-class industrial tool supplier that can be the best solution for you.