In the complex world of industrial machinery, ensuring seamless and efficient fluid transfer between stationary and rotating components is paramount. This is where a dual flow rotary union (also known as duo flow rotary union, dual channel rotary joint, or 2 passage rotary union) steps in, offering a sophisticated solution that revolutionizes fluid dynamics.

In this article, we’ll delve deeper into the fascinating world of these remarkable devices, exploring their intricate design, operational principles, and the diverse applications where they shine.

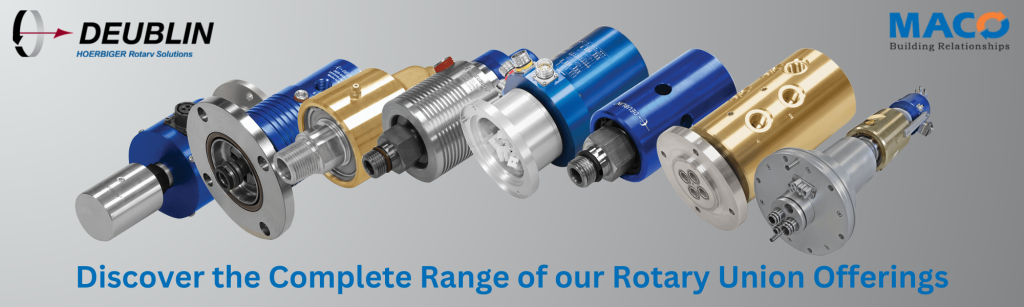

Check out our world-class rotary unions here.

Understanding the Design: A Combination of Engineering and Precision

At its core, a dual flow rotary union is a mechanical marvel designed to simultaneously transfer two separate fluids or gases.

This unique feat is achieved through meticulous engineering, combining high-quality seals, robust bearings, and specialized housing to enable continuous rotation without compromising fluid integrity.

The design typically features two distinct channels or passages, each dedicated to a specific medium.

Key Components: The Powerhouse Behind the Performance

Seals

The unsung heroes of a rotary union, seals play a critical role in ensuring leak-proof operation. These specially designed seals withstand rotational forces and pressure differentials, guaranteeing long-term reliability and preventing unwanted intermixing of fluids.

Bearings

Smooth and frictionless rotation is crucial for optimal performance. High-performance bearings, meticulously chosen for the specific application, minimize wear and tear, contributing to the longevity and efficiency of the rotary union.

Housing

The robust housing serves as a protective shield for the internal components. Often engineered from high-grade materials, it ensures structural integrity and withstands harsh industrial environments.

Fluid Dynamics in Action: Where Versatility Meets Efficiency

Dual flow rotary unions excel in scenarios demanding the simultaneous transfer of two distinct media. This versatility finds applications across various industries, including:

Pneumatic systems

Seamlessly managing airflow alongside hydraulic systems requiring fluid transfer.

Printing machinery

Precisely handling the concurrent flow of inks and coolants for optimal printing quality.

Food and beverage processing

Efficiently transferring liquids and gases in production lines.

Textile manufacturing

Maintaining a consistent flow of water and lubricants in weaving and knitting machines.

Advantages of Dual Flow Rotary Unions: Beyond Technical Brilliance

Enhanced Efficiency

By eliminating the need for separate transfer systems for each medium, dual flow rotary unions streamline processes and boost overall operational efficiency.

Compact Design

These space-saving marvels are ideal for installations with limited space, a valuable asset in crowded industrial environments.

Minimized Downtime

Uninterrupted and reliable fluid flow translates to reduced downtime and increased productivity.

Customization Options

Manufacturers often offer a range of customizable features to tailor rotary unions to specific application requirements, ensuring a perfect fit for diverse industrial needs.

Deublin’s Advanced Offering for Dual Flow Rotary Union

Whether your application requires single or multiple passages, Deublin offers an extensive range of multimedia rotary unions. You can elevate your operational efficiency and minimize downtime with Deublin’s durable multi-passage Rotary Unions.

For instance, in scenarios involving the transfer of two distinct media, Deublin’s multi-passage 2620 series unions feature two separate passages equipped with well-balanced mechanical seals.

The seal design is optimized for prolonged operation and an extended lifespan. This dual-passage rotary union is specifically recommended for applications such as machine tool spindles, diaphragm chucks, or clamping and unclamping processes.

A Cornerstone of Industrial Innovation

In the ever-evolving landscape of industrial engineering, dual flow rotary union’s ability to handle dual media simultaneously brings a new level of functionality and efficiency to fluid transfer systems.

As industries strive for continuous improvement, these remarkable devices remain a key player in ensuring optimal performance and reliability in rotating equipment.

Frequently Asked Questions

1. What are the main advantages of using dual-flow rotary unions over single-flow options?

Dual flow unions enable the simultaneous transfer of two fluids, saving space, simplifying systems, and boosting efficiency. They also reduce complexity and potential leak points compared to using separate unions.

2. What types of fluids can dual-flow unions handle?

They can handle a wide range, including liquids, gases, and even combinations like air and hydraulic fluid. However, compatibility with specific fluids depends on the materials and seals used in the union.

3. What are the typical pressure and temperature ranges for dual flow unions?

These vary depending on the specific model and its components. Generally, they can handle moderate to high pressures and temperatures, but consulting the manufacturer’s specifications is crucial.

4. How do the seals in a dual flow union prevent the mixing of the two fluids?

High-quality, precision-engineered seals create separate channels within the union, ensuring no leakage or cross-contamination between the fluids.

5. What are the maintenance requirements for dual flow unions?

Regular inspections for leaks and wear are essential. Depending on the application and usage, periodic seal replacements and lubrication might be necessary.

6. Are there different types of dual-flow unions available?

Yes, several types exist, including compact models for space-constrained applications, high-pressure models for demanding tasks, and even options with additional features like electrical slip rings.

7. What are some common applications for dual-flow unions?

They are used in various industries, including:

- Pneumatic and hydraulic systems

- Printing machinery

- Food and beverage processing

- Textile manufacturing

- Robotics and automation

8. Can dual flow unions be customized for specific needs?

Yes, many manufacturers offer customization options like material selection, port sizes, and pressure ratings to tailor the union to your specific application requirements.

9. How are dual flow unions typically installed?

Installation details depend on the model and application. Generally, they require a secure connection to both stationary and rotating components within the system.

10. Where can I find more information about specific dual flow rotary unions of Deublin?

The website of Deublin as well as Maco Corporation contains all the information about dual-flow rotary unions. If you would like to know more about the diverse offerings of Deublin Unions or have any requirements for the same, you can directly talk to our product managers. Please send a mail, call our toll-free number, or submit a callback request.

Conclusion

Dual flow rotary unions represent a significant advancement in the realm of fluid dynamics. Their versatility, efficiency, and adaptability make them an invaluable asset across various industries. As technology continues to evolve, we can expect even more innovative designs and applications for these remarkable devices, further shaping the future of fluid transfer in the industrial world.