CNC (Computer Numerical Control) machines are like super-smart tools controlled by computers. They make things with amazing accuracy and do it over and over again perfectly. Let’s learn more about them, including the various types of CNC machines available in modern manufacturing.

Check Our Exclusive Range of Deublin Rotary Unions for CNC & Other Machines

Check Our Exclusive Range of Deublin Rotary Unions for CNC & Other Machines

Why Are CNC Machines Special?

CNC machines are special because they follow instructions from computers to do their work. This makes them really precise and helps make things faster and better than before. You can think of them as robotic helpers in manufacturing. And understanding the various types of CNC machines is crucial for anyone venturing into the world of modern manufacturing.

They can make really tricky shapes with no mistakes. Plus, they can make the same thing again and again exactly the same, which is super handy for making lots of stuff. Imagine making hundreds of identical parts without any errors – that’s what CNC machines do!

Where Do We See CNC Machines?

You can find CNC machines in lots of places! They help make aeroplanes, cars, and even medical devices. Basically, anywhere that needs really accurate parts, you’ll find CNC machines doing their thing. They’re like the behind-the-scenes heroes of manufacturing!

So, CNC machines are like super-powered tools that make manufacturing easier and better. They’re pretty awesome, and they’re used all over the world to make all kinds of things! From tiny screws to massive aeroplane parts, CNC machines play a vital role in creating the things we use every day. Now let’s explore it in detail.

Types of CNC Machines

CNC machines are available in different varieties, each tailored to tasks. From CNC milling machines to CNC lathes, there are numerous types of CNC machines tailored to different machining needs. For example, CNC routers and plasma cutters are also among the types of CNC machines commonly used in woodworking and metal fabrication, respectively. Let’s explore few of them in detail.

CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a workpiece, creating complex shapes and features. They’re commonly used in industries like automotive and aerospace for precise machining.

CNC Lathes

CNC lathes rotate the workpiece while cutting tools shape it into cylindrical or symmetrical forms. They’re ideal for producing shafts, bolts, and other cylindrical components with high precision.

CNC Plasma Cutters

CNC plasma cutters use a high-velocity jet of ionized gas to cut through electrically conductive materials like steel and aluminum. They’re widely used in metal fabrication for cutting intricate shapes and designs.

CNC Routers

CNC routers utilize rotating bits to carve designs into materials such as wood, plastic, and metal. They’re popular in woodworking, sign-making, and prototyping industries for their versatility and accuracy.

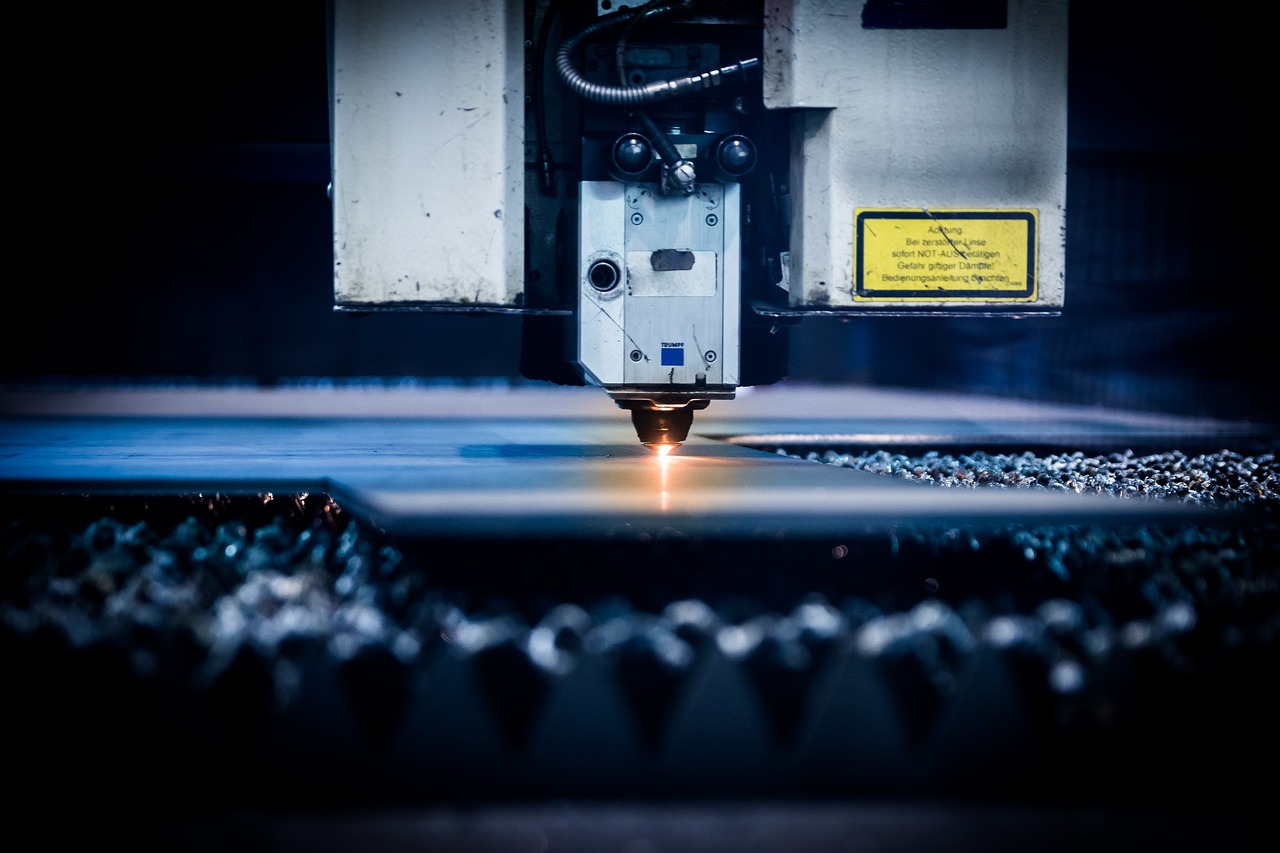

CNC Laser Cutters

CNC laser cutters employ a high-powered laser beam to cut through various materials with precision. They’re used in industries ranging from manufacturing to arts and crafts for cutting intricate patterns and shapes.

CNC Waterjet Cutters

CNC waterjet cutters use a high-pressure stream of water mixed with abrasive particles to cut through materials like metal, stone, and glass. They’re valued for their ability to cut thick materials with minimal heat-affected zones.

Each type of CNC machines has its own set of capabilities and applications, catering to the diverse needs of modern manufacturing. By understanding the strengths and limitations of various types of CNC machines, manufacturers can select the best equipment for their specific applications, optimizing productivity and quality.

Do Not Forget to Explore Our Range of Product Offerings for Diverse Industries

Do Not Forget to Explore Our Range of Product Offerings for Diverse Industries

CNC Machines Parts or Components

For any machine to work perfectly, its parts or components need to be harmony. The same is true for CNC Machine also. Now, let’s understand the common CNC machines parts.

Here’s a list of commonly used CNC machines parts or components.

- Controller: The brain of the CNC machine, which interprets G-code instructions and controls the movement of the machine.

- Drive System: Motors, servos, or actuators that move the machine’s axes according to the controller’s commands.

- Tooling: Cutting tools such as end mills, drills, and inserts used to shape or remove material from the workpiece.

- Workholding: Devices like vises, chucks, and fixtures that secure the workpiece in place during machining.

- Spindle: The rotating shaft that holds the cutting tool and provides power for cutting operations.

- Coolant System: Pumps, tanks, hoses, and nozzles used to deliver coolant to the cutting zone to reduce heat and friction.

- Enclosure: The protective housing that covers the machine and contains coolant, chips, and debris generated during machining.

- Linear Guides: Rails and bearings that guide the movement of the machine’s axes for precise positioning.

- Control Panel: Interface for operators to input commands, monitor machine status, and adjust settings.

- Safety Features: Emergency stop buttons, interlocks, guards, and sensors designed to protect operators and prevent accidents.

- Electronics: Circuit boards, wiring harnesses, and sensors responsible for transmitting signals and data between components.

- Coolant Filtration System: Filters and separators that remove contaminants from coolant to maintain its effectiveness.

- Lubrication System: Pumps, lines, and fittings that deliver lubricant to moving parts to reduce friction and wear.

- Chip Conveyor: System for removing chips and swarf from the machine’s work area to keep it clean and prevent damage to components.

- Machine Bed: The foundation or base of the machine that supports all other components and provides stability during operation.

These are just some of the key parts or components found in CNC machines, each playing a vital role in the machining process.

How CNC Machines Work

Ever wondered how CNC machines pull off their magic? Let’s uncover the mystery behind their operation!

Computer Control

So, picture this: CNC machines are like obedient robots taking orders from computers. They follow instructions from computer programs, known as CNC code or G-code. These instructions tell them exactly what to do – where to move, how fast to move, and when to start and stop cutting. It’s like giving your CNC machine a to-do list and watching it get things done!

Precision Movement

Now, here’s where things get really cool. CNC machines use motors and gears to move their cutting tools with incredible precision. The motors get signals from the computer and move the tools along different axes, like X, Y, and Z. This precise movement allows CNC machines to make accurate cuts and shapes. It’s like they’ve got a built-in GPS guiding them every step of the way!

Cutting and Shaping

Once your CNC machine gets its marching orders, it gets down to business cutting and shaping the material according to the programmed design. Whether it’s milling, turning, drilling, or another machining operation, your CNC machine is on it. And the best part? It’s all happening just the way you told it to!

Feedback and Monitoring

But wait, there’s more! Throughout the machining process, your CNC machine keeps an eye on things to make sure everything’s running smoothly. It might use sensors and feedback systems to check for issues like tool wear or material inconsistencies. If anything’s amiss, your CNC machine can make adjustments on the fly to keep things on track.

Endless Possibilities

With CNC machines, the sky’s the limit! They can follow precise instructions and perform complex tasks with ease, opening up a world of possibilities in manufacturing. Whether you’re making custom parts or mass-producing intricate components, CNC technology puts the power in your hands to bring your ideas to life – with pinpoint precision!

Advantages of CNC Machining

Alright, let’s talk about why CNC machining is the bee’s knees when it comes to making stuff. Buckle up, because you’re in for a ride!

Precision Perfection

First things first – precision. With CNC machining, you can kiss goodbye to wonky parts and rough edges. Your CNC machine is like a surgeon with a scalpel, cutting and shaping with laser-like accuracy. So whether you’re making tiny gears or massive engine blocks, you can bet your bottom dollar they’ll come out just right.

Repeatable Results

Now, here’s where things get really sweet. Ever tried making the same thing over and over again by hand? It’s a nightmare! But with CNC machining, it’s a walk in the park. You program your design once, and your CNC machine churns out identical parts like nobody’s business. It’s like having a cloning machine in your workshop – but way cooler!

Flexibility Galore

Think CNC machining is just for one-trick ponies? Think again! Your CNC machine is a jack-of-all-trades, ready to tackle any task you throw its way. Need to switch gears and make something completely different? No problemo! Just tweak the program, and your CNC machine is good to go. It’s like having a Swiss Army knife in your toolbox – versatile, reliable, and always ready for action.

Time is Money

Let’s talk about everyone’s favorite topic – money. With CNC machining, time is literally money. Think about it: every minute your CNC machine is churning out parts, you’re saving precious time and moolah. No more wasting hours on manual labor or waiting for a skilled machinist to work their magic. Your CNC machine works fast, works smart, and gets the job done in record time.

The Diverse World of CNC Machining: Applications Across Industries

Computer Numerical Control (CNC) machining has revolutionized manufacturing. These versatile machines take computer-generated designs and translate them into precise movements, controlling tools to cut and shape a vast array of materials. The applications of CNC machined parts are truly staggering, spanning nearly every industry imaginable. Let’s delve into some of the key sectors that rely on CNC technology:

Powering the Wheels of Industry: Automotive and Aerospace

The transportation sector is a major driver of CNC machining. From engine components like pistons and valves to intricate parts in transmissions and differentials, CNC mills and lathes ensure precise tolerances and high-volume production. The aerospace industry utilizes CNC machining for even more critical parts. Airplane wings, landing gear components, and lightweight yet robust fuselage parts are all meticulously crafted using CNC technology.

Consumer Electronics: The Tech We Use Every Day

The sleek корпуса (korpusa – Russian for “body”) of your laptop or smartphone? Likely CNC machined from aluminum. The intricate heat sinks that cool powerful processors? Often CNC milled. Even the tiny components on a circuit board can be produced with the precision of CNC machining.

Building Our World: Construction and Architecture

CNC machining isn’t just for metal. Woodworking shops and architectural firms utilize CNC routers to create intricate moldings, customized cabinetry, and even complex building components. These machines allow for precise cuts and designs that would be nearly impossible to achieve with traditional methods.

Keeping Us Healthy: The Medical Field

The medical field relies on the accuracy and repeatability of CNC machining for a wide range of applications. Surgical instruments, prosthetic limbs, and even delicate components in pacemakers are all often CNC machined. This ensures consistent quality and functionality in these life-saving tools.

Beyond the Obvious: Everyday Applications

The applications of CNC machined parts extend far beyond these major industries. Custom parts for bicycles, intricate components in robotics, and even molds for plastic toys are all frequently produced using CNC technology.

This is just a glimpse into the vast world of CNC machining applications. As CNC technology continues to evolve and become more affordable, we can expect to see even more innovative uses emerge in the years to come. The precision, versatility, and efficiency of CNC machining make it a cornerstone of modern manufacturing, shaping the world around us in countless ways.

Common Challenges and Solutions in CNC Machining

Okay, let’s talk about the not-so-fun stuff – the challenges you might face when using CNC machines. But don’t worry, we’ve got solutions!

Tool Wear Woes

First up: tool wear. Over time, the cutting tools on your CNC machine can wear down, leading to less-than-perfect cuts and shapes. But fear not! Regular maintenance and tool replacement can help keep your CNC machine running smoothly and your parts looking sharp.

Material Deformation Drama

Next, let’s talk about material deformation. Some materials, like metal, can be prone to warping or bending during machining. To combat this, try using proper machining techniques and cooling methods to keep your materials in check. With a little finesse, you’ll be machining like a pro in no time!

Programming Predicaments

Ah, programming – the heart and soul of CNC machining. But sometimes, programming errors can throw a wrench in your plans. The key here is to double-check your code and run simulations to catch any potential issues before they become problems. With a little attention to detail, you’ll be writing flawless code like a seasoned programmer.

Surface Finish Snags

Last but not least, let’s talk about surface finish. Sometimes, your parts might come out with rough or uneven surfaces, which can affect their quality and appearance. But fear not! Adjusting your machining parameters and using the right cutting tools can help you achieve the perfect finish every time. It’s all about finding the sweet spot and dialing it in just right.

Operator Training and Safety for CNC Machines

Alright, let’s talk safety first. When you’re working with CNC machines, safety always comes first. Make sure you’re wearing the proper protective gear, like safety glasses and gloves, and follow all safety protocols and guidelines. Remember, your safety is non-negotiable!

Now, let’s talk training. Operating a CNC machine isn’t exactly rocket science, but it does require a certain level of skill and know-how. Make sure you receive proper training on how to use your CNC machine safely and effectively. Familiarize yourself with the machine’s controls, programming software, and maintenance procedures. The more you know, the better equipped you’ll be to handle any challenges that come your way.

And don’t forget to keep learning! CNC machining is an ever-evolving field, with new technologies and techniques emerging all the time. With the right training and a commitment to safety, you’ll be a CNC machining pro in no time!

Rotary Union in CNC Machines

Alright, let’s talk about a little something called rotary union – the unsung hero of coolant systems in CNC machines!

Coolant Control

Picture this: You’re machining away on your CNC machine, and things are heating up – literally. That’s where the coolant system comes in, keeping your tools and workpieces cool during machining. But without a rotary union, your coolant system wouldn’t be able to deliver coolant to your tools as they move around. That’s where the rotary union comes in, allowing coolant to flow freely to your tools, no matter how they’re positioned. It’s like having a personal air conditioner for your CNC machine!

Smooth Operation

But the benefits of a rotary union don’t stop there. By ensuring a steady supply of coolant to your tools, a rotary union helps maintain consistent temperatures and lubrication levels during machining. This not only prolongs the life of your cutting tools but also improves the quality and accuracy of your machined parts. It’s like giving your CNC machine a spa day – smooth, refreshing, and oh-so-good for performance!

Check  Check Out Our Complete Range of Deublin Rotary Unions

Check Out Our Complete Range of Deublin Rotary Unions

Deublin’s Offering: Rotary Unions for CNC Machines

Now, let’s talk about Deublin – the go-to solution for rotary unions in CNC machines!

Quality and Reliability

When it comes to rotary unions, Deublin is the name you can trust. With decades of experience and a reputation for quality and reliability, Deublin rotary unions are the gold standard in the industry. Whether you’re machining metal, plastic, or anything in between, you can count on Deublin rotary unions to deliver consistent performance, day in and day out.

Precision Engineering

But what sets Deublin rotary unions apart from the rest? It’s simple – precision engineering. Each Deublin rotary union is carefully crafted to exacting specifications, ensuring a perfect fit and seamless operation in your CNC machine. With features like precision bearings, leak-proof seals, and durable construction, Deublin rotary unions are built to last, even in the most demanding machining environments.

Customer Satisfaction

But don’t just take our word for it – let our customers do the talking! From small job shops to large manufacturing plants, customers around the world trust Deublin rotary unions to keep their CNC machines running smoothly. With a commitment to customer satisfaction and a track record of excellence, Deublin is the clear choice for all your rotary union needs.

Frequently Asked Questions(FAQs)

What exactly are CNC machines, and why should I care about them in manufacturing?

– CNC machines are like super-smart tools controlled by computers. They’re essential in manufacturing because they make things really accurate and can repeat tasks perfectly, which is crucial for producing high-quality products efficiently.

How many types of CNC machines are there?

– Sure! There are various types of CNC machines, each with its own speciality. For instance, milling machines shape materials using rotating cutting tools, while lathes are great for making cylindrical shapes. There are also plasma cutters, routers, laser cutters, and waterjet cutters, each with their unique functions and applications.

How do CNC machines actually work? It seems pretty complicated.

Let’s simplify it. CNC machines follow instructions from computer programs, called CNC code or G-code, to move their cutting tools precisely and create the desired shapes. It’s like giving them a set of instructions, and they follow them to the letter to make your parts just right. And they perform various tskes according to their types also.

In summary, we can say that the diversity of types of CNC machines reflects the versatility and adaptability of modern manufacturing processes.

I’m interested in the advantages of using CNC machining. Can you tell me more about them?

– Absolutely! CNC machining offers several advantages, including precision (they make things really accurately), repeatability (they can make the same thing again and again perfectly), flexibility (they can switch tasks easily), and efficiency (they save time and money).

Are there any common problems I should be aware of when using CNC machines, and how can I solve them?

– Yes, like any technology, CNC machines can have their challenges. Things like tool wear, material deformation, programming errors, and surface finish issues can pop up. But don’t worry! With regular maintenance, proper techniques, and attention to detail, you can overcome these hurdles easily.

Can you tell me more about the CNC machine’s spare parts list?

Sure. Here is a brief note on the CNC machine’s spare parts list. Remember this is not an exhaustive one.

- Cutting Tools: End mills, drills, taps, reamers, inserts, and tool holders.

- Coolant System Components: Coolant pumps, filters, hoses, nozzles, and coolant tanks.

- Machine Tool Accessories: Vises, clamps, rotary tables, chucks, collets, and tooling plates.

- Machine Components: Bearings, belts, pulleys, gears, screws, nuts, and linear guides.

- Electrical Components: Motors, drives, controllers, sensors, switches, and cables.

- Lubrication System Parts: Lubricant pumps, reservoirs, lines, fittings, and grease.

- Spindle Parts: Spindle motors, bearings, belts, pulleys, and drawbars.

- Enclosure and Safety Components: Doors, windows, panels, interlocks, and safety switches.

- Control System Components: Circuit boards, displays, keyboards, and control panels.

- Maintenance Tools and Supplies: Lubricants, cleaners, brushes, wrenches, and gauges.

This list covers a range of spare parts commonly used in CNC machines to ensure smooth operation and timely maintenance. Depending on the specific type and model of CNC machine, additional spare parts may be required.

I’m curious about rotary unions mentioned in the blog. What are they, and why are they important in CNC machines?

– Rotary unions play a crucial role in coolant systems in CNC machines. They ensure a steady supply of coolant to the cutting tools, keeping them cool and lubricated during machining, which helps maintain consistent temperatures and improves the quality of the machined parts.

Who is Deublin, and why should I trust them for rotary unions?

– Deublin is a trusted name in the industry, known for its quality and reliability. They’ve been in the business for decades and are experts in precision engineering, ensuring that their rotary unions are built to last and perform flawlessly in CNC machines.

Maco Corporation is mentioned as the exclusive supplier of Deublin rotary unions in India. Why is that significant?

– It’s significant because it means you can rely on Maco Corporation to provide you with top-notch rotary unions for your CNC machines. They’re committed to customer satisfaction and ensuring that you have access to the best products and support for your manufacturing needs.

I’m interested in learning more about CNC machining. Where can I find additional resources?

– There are plenty of resources available online, including tutorials, forums, and industry publications. You can also reach out to experts in the field or attend workshops and training sessions to expand your knowledge and skills in CNC machining.

And there you have it – a deep dive into the world of CNC machining and the essential role of rotary unions in keeping your machines running smoothly.

From the precision of CNC machines to the versatility of their applications, it’s clear that CNC technology has revolutionized the manufacturing industry. With CNC machines by your side, there’s no limit to what you can create – from aerospace components to medical devices to everyday consumer goods.

But let’s not forget the unsung heroes of CNC machining – rotary unions. These small but mighty components play a crucial role in ensuring optimal performance and efficiency in your CNC machines. And when it comes to rotary unions, there’s one name you can trust – Deublin.

With decades of experience and a reputation for quality and reliability, Deublin rotary unions are the gold standard in the industry. And here in India, you can count on Maco Corporation to be your trusted partner in supplying Deublin rotary unions for all your CNC machining needs. As the exclusive supplier of Deublin rotary unions in India, Maco Corporation is committed to providing top-notch products and unparalleled customer service.

So whether you’re a small shop or a large manufacturing plant, you can rely on Maco Corporation to deliver the rotary unions you need to keep your CNC machines running smoothly and efficiently.

Feel free to contact us by mail, phone or live chat on our site at the bootom right corner.