In industries, different types of welding mechanisms are required to build new products and tools. Flash butt welding is a type of electrical resistance welding procedure. This welding process is used to join two components through which energy is transferred by the resistance heat generated by the parts themselves. In regular life, we see some examples of flash butt welding, for example, the railway rails, and the bicycle wheel rims. The entire process of flash butt welding can be done manually, however, in maximum industries, the process depends on machines, which are fully automatic or semi-automatic.

Upset weld is another name for butt weld. These days the demand for this welding process is huge in different industries. The connection between the mobile and fixed parts creates electric current and this power is referred to as heat for welding. When the two parts join, sparks of electric power are seen. The spark is the result of metal loss. The upsetting system includes a greater current to accelerate the mobile components towards the permanent part. Welding or joining two parts of the component requires the highest speed and pressure throughout the process.

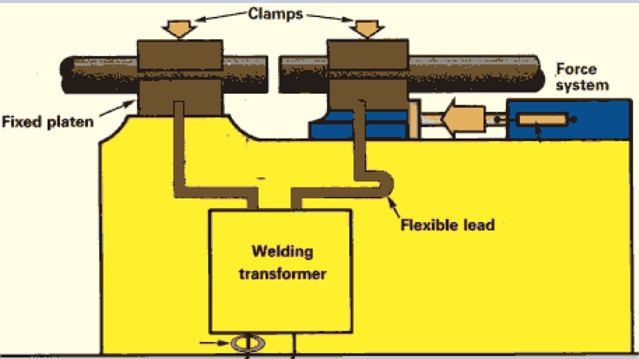

The process of flash butt welding:

Flash welding is a process where two components are joined through current. When the wheel moves along with the work piece for welding, current pulses are generated. The energy through which the two components are joined is mostly the resistance heat.

A current is applied to join the metal pieces when they are separated. At this time the metal component starts to melt due to the resistant heat and an arc is generated between the two parts.

The presence of the introduction of the arc is known or called ‘flash time’. The melted parts become soft and flexible at this time. With extreme force, the ends of the two parts are joined. Any kind of filler metal is not required in this situation.

An electric control system is required to provide a reliable welding process. A clamping mechanism attached to horizontally placed cylinders is needed to avoid slippage during welding. The flashing adds warmth to the process gradually, softens the end of the components, and removes oxides and impurities from the metal.

Advantages of flash butt welding:

- It is a fast and flawless process.

- It can be done both manually or with a machine.

- Power requirement is less in this process.

- Weld surface preparation is not needed.

- The process offers a strength factor up to 100%.

Applications:

- Used to join metal sheets, bars, rod fittings, etc.

- Automotive and aircraft products use this process.

- Household appliances, steel industries, and farm tools use this technique.

At Maco Corporation, we provide Mobile Flash Butt Welding equipment’s for mainly the railways and related construction project works. Visit us at our inbox and leave us an enquiry.